Using your Edger...

Special cases

3-76

3.5.3 E

DGING

THE

LEFT

LENS

WITH

DIFFERENT

PARAMETERS

FROM

THOSE

OF

THE

RIGHT

LENS

3.5.3.1 P

RINCIPLE

>

If the left and right lenses of your job do not have the same characteristics, you may modify the edging data

from one lens to another using the buttons available in the Edging tab.

C

AUTION

!

For the same job, the following characteristics cannot be modified from one lens to another:

•

Lens material

•

Finishing type

•

Polishing type.

You may only modify the following characteristics:

•

Lens type

•

Sub-finishing type

•

Safety-bevel type.

3.5.3.2 P

ROCEDURE

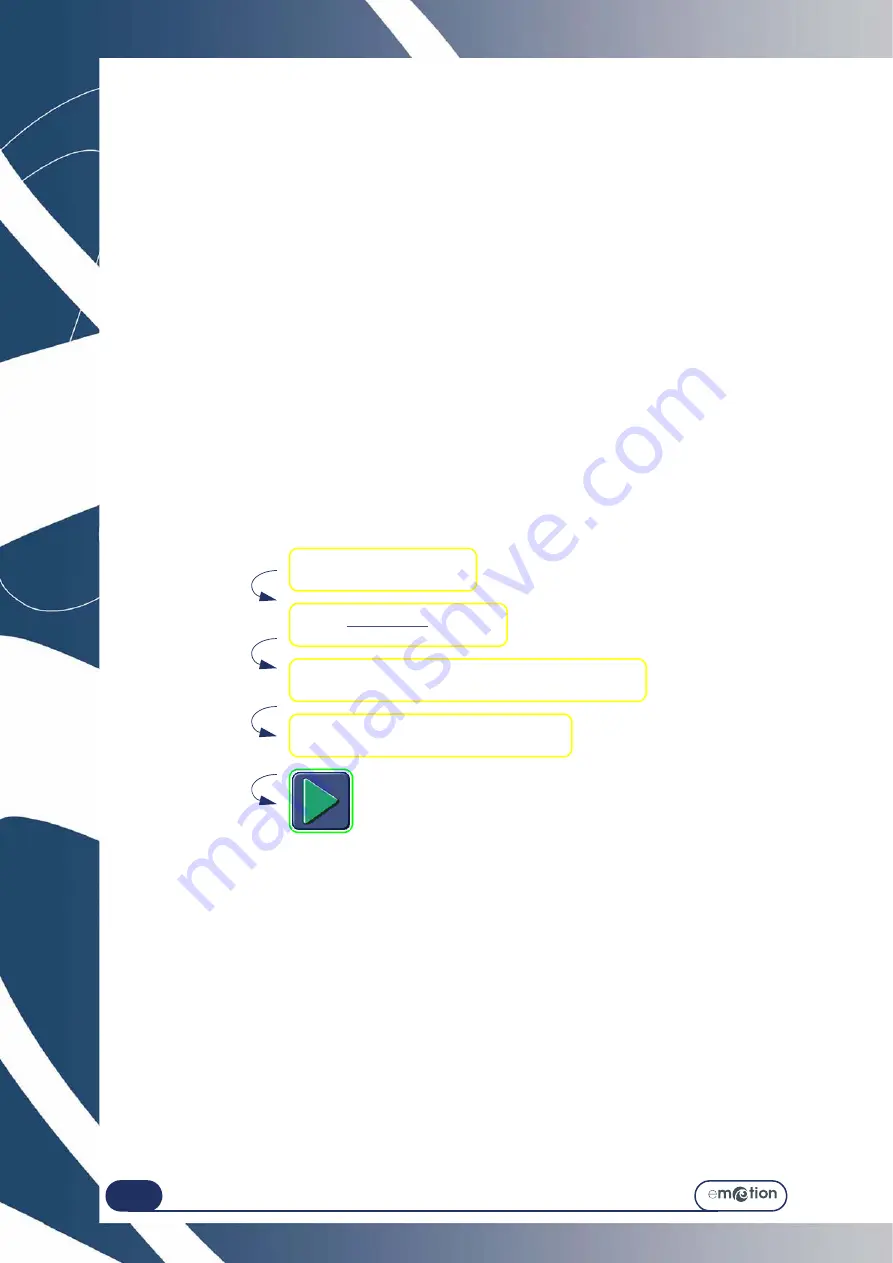

To modify the parameters from one lens to another, proceed as follows.

Note: Using the touch screen, press the zones or buttons shown.

Flow chart 3-7: Modification of parameters from one lens to another

Change the characteristics as you wish.

Edge the first lens.

Check the parameter values.

Select the left side.

Summary of Contents for emotion

Page 1: ...Operation manual...

Page 3: ......

Page 9: ...Table of contents...

Page 10: ...REVISION FOLLOW UP Revision 01 Page New Modified Item New document...

Page 11: ...3 10...

Page 12: ...1 INSTALLATION...

Page 15: ...Installation Unpacking the machine 1 14...

Page 17: ...Installation Removing the shipping rails 1 16...

Page 23: ...Installation Water connections 1 22...

Page 25: ...Installation Electrical connections 1 24 1 3 2...

Page 28: ...2 SAFETY PRECAUTIONS...

Page 29: ...2 28...

Page 31: ...Safety precautions Safety 2 30...

Page 33: ...2 32 Safety precautions Recommendations...

Page 34: ...3 USING YOUR EDGER...

Page 35: ...3 34...

Page 41: ...3 40...

Page 45: ...Using your Edger General principles of use 3 44 Pin 1 2 3 5 Blocker head Blocker arm 4...

Page 51: ...Using your Edger General principles of use 3 50...

Page 75: ...Using your Edger Special cases 3 74...

Page 87: ...Using your Edger Special cases 3 86...

Page 94: ...4 CONFIGURATION...

Page 95: ...4 94...

Page 102: ...Configuration Configuration of finishing parameters default values 4 101...

Page 107: ...Configuration Correction of frame and lens values 4 106...

Page 112: ...5 MAINTENANCE...

Page 113: ...5 112...

Page 117: ...Maintenance Visualising the components 5 116...

Page 119: ...Maintenance Task list 5 118...

Page 121: ...Maintenance Maintenance of the touch screen unit 5 120 Illustration 5 1 Scanform...

Page 124: ...Maintenance Maintenance of the Scanform unit 5 123...

Page 125: ...Maintenance Maintenance of the Scanform unit 5 124 Illustration 5 1 Centering blocking system...

Page 131: ...Maintenance Regular maintenance of the edger 5 130...

Page 135: ...Maintenance Regular maintenance of the edger 5 134...

Page 147: ...Maintenance Regular maintenance of the edger 5 146...

Page 149: ...Maintenance Handling the covers 5 148...

Page 151: ...Maintenance Preventive maintenance 5 150...

Page 156: ...Maintenance Adjustments 5 155...

Page 157: ...Maintenance Adjustments 5 156 Screen 5 4 Feeling adjustment...

Page 159: ...Maintenance Adjustments 5 158 Screen 5 5 Adjusting the sizes Screen 1...

Page 163: ...Maintenance Adjustments 5 162 Screen 5 6 Adjustment of the flush of the mill bit...

Page 165: ...Maintenance Adjustments 5 164 Screen 5 7 Adjustment of the touch screen...

Page 167: ...Maintenance Adjustments 5 166 Screen 5 8 Example of a setting values display screen...

Page 169: ...Maintenance Adjustments 5 168...

Page 173: ...Maintenance Consulting the statistics 5 172...

Page 196: ...6 TESTS...

Page 197: ...6 196...

Page 203: ...Tests Operating principle 6 202...

Page 204: ...7 TECHNICAL SPECIFICATIONS...

Page 205: ...7 212...

Page 209: ...Technical specifications Technical specifications 7 216...

Page 210: ...2 rue Roger Bonnet 27340 PONT DE L ARCHE FRANCE Tel 33 02 32 98 91 32 Fax 33 02 35 02 02 94...