25

Laddermill Owner’s Manual—2017

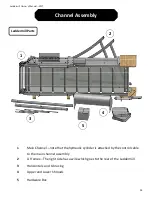

Channel Assembly

The Laddermill comes palle zed by truck, and must be taken off the pallet, unloaded

and transported to the install loca on. The only heavy part is the channel assembly

which should be handled by at least four people. To remove the channel assembly from

the pallet, remove six lag screws that hold the lengths of wood that are a ached to the

channels with bolts.

It is best to have three 4-wheel moving dollies on hand to transport the channel assem-

bly from the truck. If the terrain is rough, strap the assembly to the dollies. The other

parts are carried by hand.

If the machine must be moved upstairs, it is best to have extra help as the channels are

heavy and awkward. Li ing straps placed around the bo om of the machine can help

spread the load.

Place moving dollies on wood supports

Summary of Contents for Laddermill Ascender

Page 2: ......

Page 4: ...ii Laddermill Owner s Manual 2017 ...