49

Heavy Haul Trailers

3.9.7

Axle/Suspension Loading

There are two different load capacities that must be considered. First is the structural capacity of the

trailer and tractor, which is how much weight the axle or axle group can physically support. The other

is the legal capacity, which is how much weight the regulations will allow each axle or axle group to

carry. Legal capacity depends entirely on the regulations under which the vehicle will be operated.

Legal capacity may be greater or less than the structural capacity depending on the region and time

of year. Never exceed the GAWR, found on the vehicles compliance label.

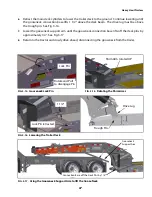

3.9.8

Altering Load Travel Height

To temporarily raise or lower the load, the gooseneck cylinders may be raised or lowered to change

the overall height. Any such adjustments are only for short distances such as clearing over railroad

tracks or under overpasses. The gooseneck MUST be returned to Shim Leg fixed support be for

continuing or damage to the trailer could occur.

WARNING!

Using the hydraulics to alter the load height may affect the suspension travel and

trailer handling, and may cause the trailer to become unstable. Travel only short distances at slow

speeds. Stability is entirely the responsibility of the operator.

3.9.9

Final Checks

Before moving the vehicle, familiarize yourself with its dimensions. Know the width and height and if

a scale is available, check the axle loads. Ensure the load is properly secure and place all loose tie

down material and other equipment into storage compartments. Make sure all safety equipment is in

place, functioning and secure.

Summary of Contents for H550 Series

Page 2: ......

Page 4: ...Heavy Haul Trailers ...

Page 15: ...Heavy Haul Trailers 8 ...

Page 30: ...21 Heavy Haul Trailers ...

Page 31: ...Heavy Haul Trailers 22 Both Sides ...

Page 32: ...23 Heavy Haul Trailers Both Sides ...

Page 52: ...43 Heavy Haul Trailers 3 5 4 Extension Load Shim Instructions ...

Page 59: ...Heavy Haul Trailers 50 ...

Page 84: ...69 Heavy Haul Trailers Date Maintenance Performed Maintenance Records ...

Page 85: ...Heavy Haul Trailers 70 Date Maintenance Performed Maintenance Records ...

Page 86: ...71 Heavy Haul Trailers Date Maintenance Performed Maintenance Records ...

Page 87: ...Heavy Haul Trailers 72 Date Maintenance Performed Maintenance Records ...

Page 88: ......