BRAILLO

l

B 650 SW2.1

22

2.8 Compressed air

This equipment requires clean, compressed air, minimum 7.0 bar @ 100 l/min., and max. temperature

50° C to the regulator to function. To make this compressed air, you will need to use some sort of

compressor. No matter what kind of compressor is chosen, there are some important things to re

-

member.

First, please read the enclosed instruction manual for the compressor!

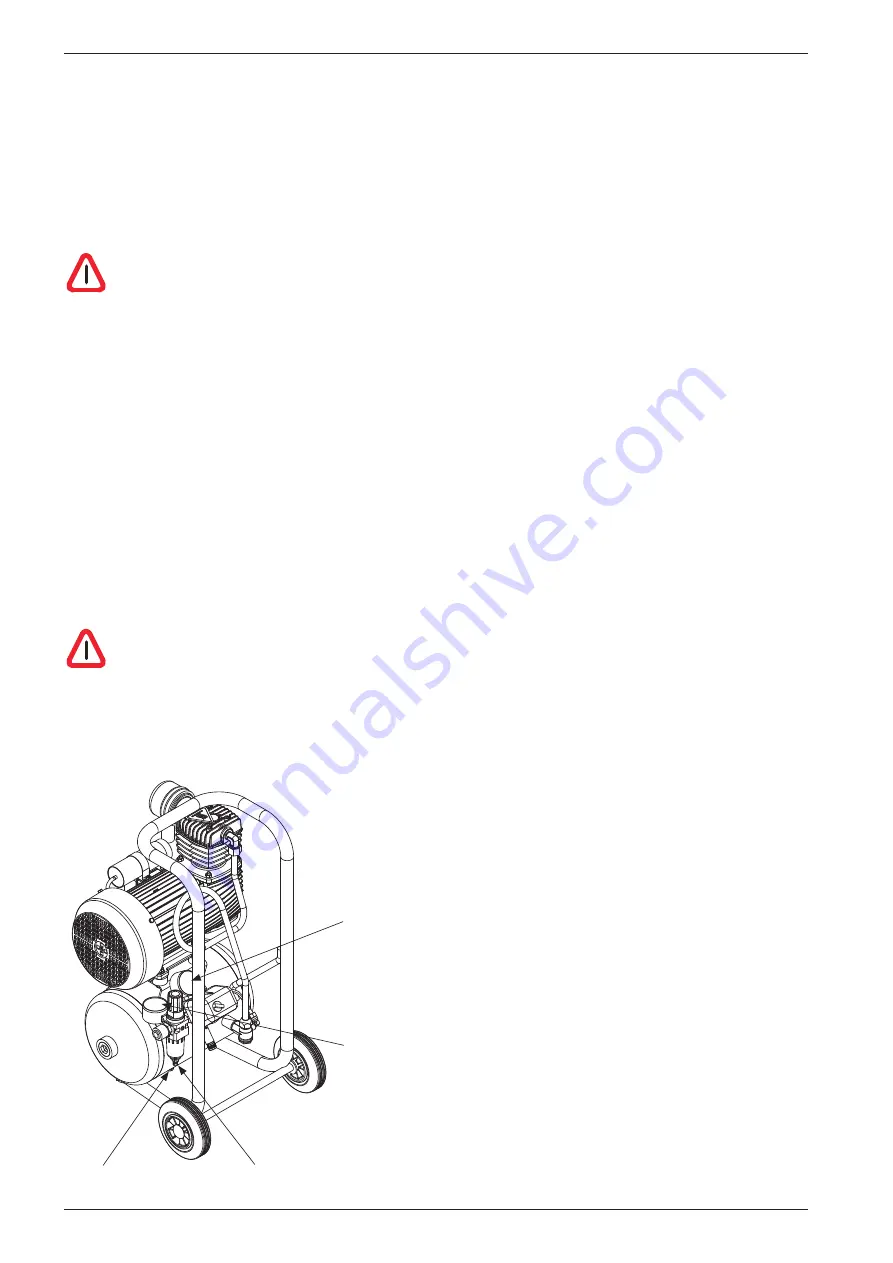

There are many different compressor types on the market, and this chapter will not deal with a

particular compressor, but will discuss the topic more in general. Please see the figure below for an

example, but refer to your compressor manual for the specific information.

Normally a compressor have two pressure gauges and a pressure regulator fitted. The first gauge is

measuring the tank pressure (before the regulator) and the second gauge is measuring the output

pressure (after the regulator). The pressure at the compressor outlet must be adjusted to approx.

seven bar. This can be controlled at the output pressure gauge.

To have long and trouble free operation, the air must be filtered and free from oil and water.

When air is compressed in a compressor, the air temperature is rising. So the air entering the tank will

be hot. When the air is cooling down, the humidity in the air will condensate inside the tank. So the

warmer and more humid the air entering the compressor is, the more water condensates inside the

tank. The compressor is lubricated with oil and small amounts of oil may also get into the tank.

This means that the tank must be drained for oil and water on a regular basis.

If the air is supplied from the smaller types of compressors delivered from Braillo Norway AS, it is

required to keep the compressor in a similar environment as described for the Printer itself. (Temper

-

ature 15 - 30°C (60 - 86°F) and rel. humidity 40 - 60%).

Tank drainage

Filter drainage

Tank pressure

gauge

Output pressure gauge (ad-

just to 7 bar)

If the compressor is placed in a more harsh

environment, it might be necessary to take

further precautions to remove oil and water

from the air.

Basic elements on a compressor: