9.4.6

Setting the Kv parameter

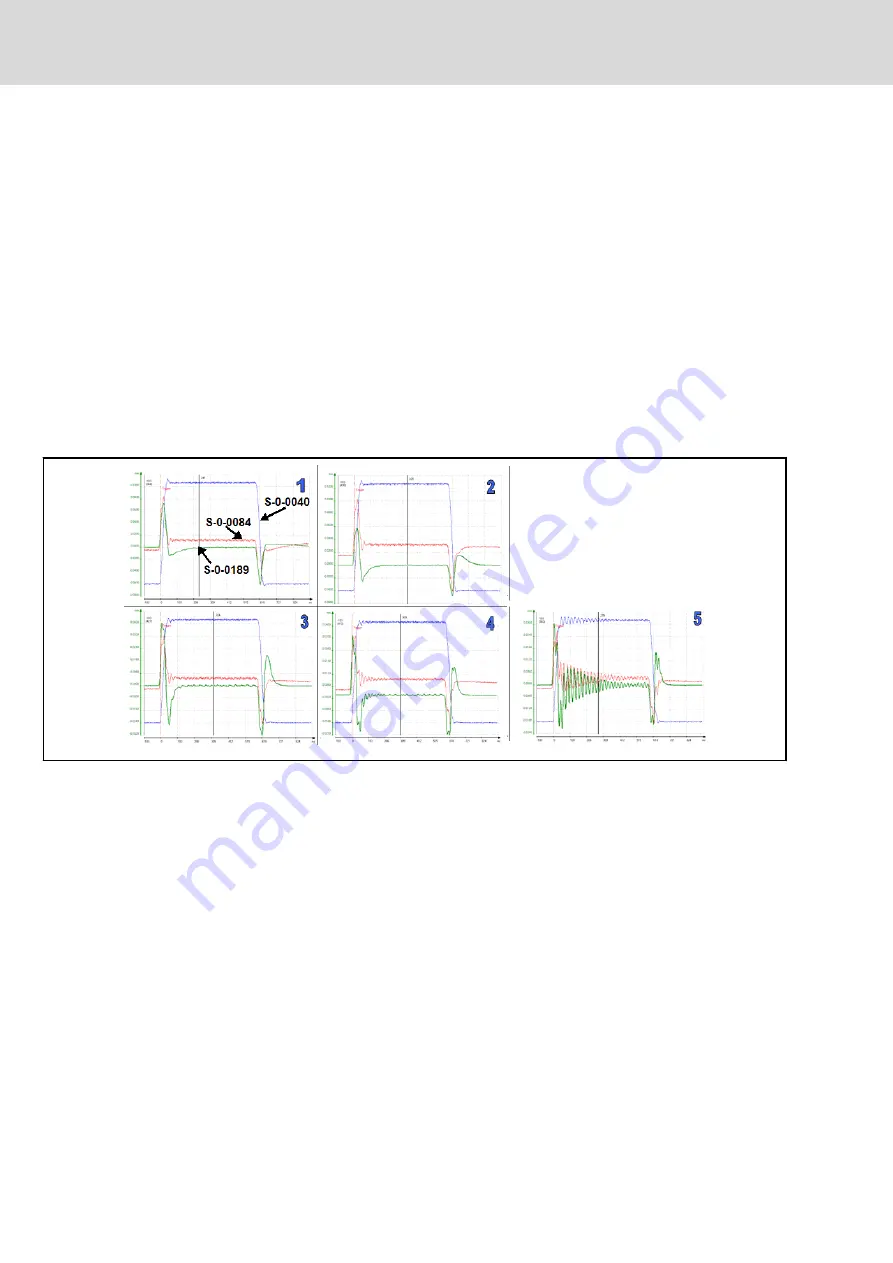

Optimize the Kv factor S-0-0104. By means of the NC program, the lag dis‐

tance S-0-0189 is measured using the oscilloscope. Increase the value of Kv

as long as necessary for the torque signal to show an oscillation. To ensure

system stability, set Kv to half the value occurring when the torque starts to

oscillate.

See the following example: The Kv factor is increased from 1 to 8, and the

following distance is measured from 0.07 mm to 0.03 mm:

1. Kv = 1,max. following distance (S-0-0189) = 0.07 mm

2. Kv = 2,max. following distance (S-0-0189) = 0.06 mm

3. Kv = 4,max. following distance (S-0-0189) = 0.04 mm

4. Kv = 6,max. following distance (S-0-0189) = 0.03 mm

5. Kv = 8,max. following distance (S-0-0189) = 0.03 mm

Since the torque signal (S-0-0084) shows an oscillation with a setting of Kv =

8, the Kv value is set to 50% of the maximum value determined, i.e., Kv = 4.

Fig. 9-21:

Setting the Kv factor

Bosch Rexroth AG

DOK-MTXMIC-EASY*******-CO06-EN-P

118/177

IndraMotion MTX micro Easy Setup for Standard Turning and Milling Machines

Commissioning the drives