30/104 About this product

Bosch Rexroth AG

, A4... with HS5E pilot control valve/Series 3x, RE 92076-01-B/10.2017

5.6.1 noise development in the unit

“Noise” consists of various components. The “noise” overall result is not just

affected by airborne noise but also by structure-borne and fluid noise.

Due to unfavorable installation and piping conditions, the sound pressure level of

the overall system can be 5 to 10 dB(A) higher than the pump's individual value.

Measures for reducing noise include, for example:

•

Low-noise containers

•

A damping ring between the pump and the pump carrier

•

Elastic pipe feedthrough

•

Damping rails below the motor

•

Installing the pump at an adequate distance from the container wall

5.6.2 Pulsation damper

With some special applications, we recommend using a pulsation damper for

operation. Due to the reduction in the pressure pulsation that is typical of pumps,

this also positively affects the noise level of the hydraulic system.

You can find information about this in data sheet RE 50142.

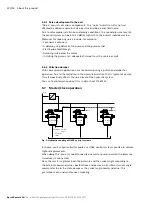

5.7 Master/slave operation

Pressure

p, Q

p

U(i)

Swivel

angle

Setpoint

value

MASTER

Slave

1

Slave

n

(α

actual

)

(α

set

)

(α

set

)

Fig. 5: Hydraulic coupling of HS5E control systems

In theory, you can hydraulically couple any HS5E control systems you like to achieve

higher displacements.

When doing this, you only need to specify one master pump to which the pressure

transducer is connected.

Now, the master regulates both the pressure and the swivel angle according to

the external command value specifications and passes on its internal swivel angle

command value to the slave pumps as the swivel angle command value. This

guarantees even and synchronous swiveling.