12

| English

1 609 92A 2HX | (14.1.16)

Bosch Power Tools

Mounting/Replacing the Application Tool/Accessory

(GOP 30-28)

If required, remove an already mounted application tool/

accessory.

For removing the application tool/accessory, loosen the

screw

6

with the hex key

7

and remove the application

tool/accessory.

Mount the requested application tool/accessory (e.g. plunge

cut saw blade

5

) in such a manner on the tool holder

4

that the

offset faces downward (see illustration on the graphics page;

marking on the application tool/accessory is readable from

above).

Turn the application tool/accessory to a position favourable

for the respective job, and allow it to engage into the cams of

the tool holder

4

. 12 different positions are possible, each

offset by 30°.

Fasten the application tool/accessory with bolt

6

. Tighten the

bolt with hex key

7

until the spring washer of the bolt faces

flush against the application tool/accessory.

Check the tight seating of the application tool/acces-

sory.

Incorrect or not securely fastened application

tools/accessories can come loose during operation and

pose a hazard.

Mounting/Replacing the Application Tool/Accessory

(GOP 40-30/GOP 55-36)

If required, remove an already mounted application tool/

accessory.

To do so, open the SDS lever

12

all the way. The application

tool/accessory will be ejected.

Mount the requested application tool/accessory (e.g. plunge

cut saw blade

5

) in such a manner on the tool holder

4

that the

offset faces downward (see illustration on the graphics page;

marking on the application tool/accessory is readable from

above).

When doing so, place the application tool/accessory in a posi-

tion which is convenient for the job at hand. Twelve different

positions are possible, each offset by 30°.

Press the application tool/accessory in the required position

firmly onto the clamping jaws of the tool holder until it is auto-

matically locked.

Check the tight seating of the application tool/acces-

sory.

Incorrect or not securely fastened application

tools/accessories can come loose during operation and

pose a hazard.

Mounting and Adjusting the Depth Stop

The depth stop

15

can be used when working with segment

and plunge cut saw blades.

If required, remove an already mounted application tool/ac-

cessory.

Slide the depth stop

15

in the required work position all the

way over the tool holder

4

onto the collar of the power tool. Al-

low the depth stop to engage. Twelve different positions are

possible, each offset by 30°.

Set the required working depth. Press shut the clamping lever

14

of the depth stop in order to fix the depth stop.

Mounting/Replacing a Sanding Sheet on the Sanding Plate

The sanding plate

9

is fitted with Velcro backing for quick and

easy fastening of sanding sheets with Velcro adhesion.

Before attaching the sanding sheet

10

, free the Velcro back-

ing of the sanding plate

9

from any debris by tapping against

it in order to enable optimum adhesion.

Position the sanding sheet

10

flush alongside one edge of the

sanding plate

9

, then lay the sanding sheet onto the sanding

plate and press firmly.

To ensure optimum dust extraction, pay attention that the

punched holes in the sanding sheet match with the holes in

the sanding plate.

To remove the sanding sheet

10

, grasp it at one of the tips and

pull it off from the sanding plate

9

.

You can use all sanding sheets, fleece pads/polishing cloth

pads of the Delta 93 mm series of Bosch accessory program.

Sanding accessories, such as fleece pads/polishing cloth

pads, are attached to the sanding plate in the same manner.

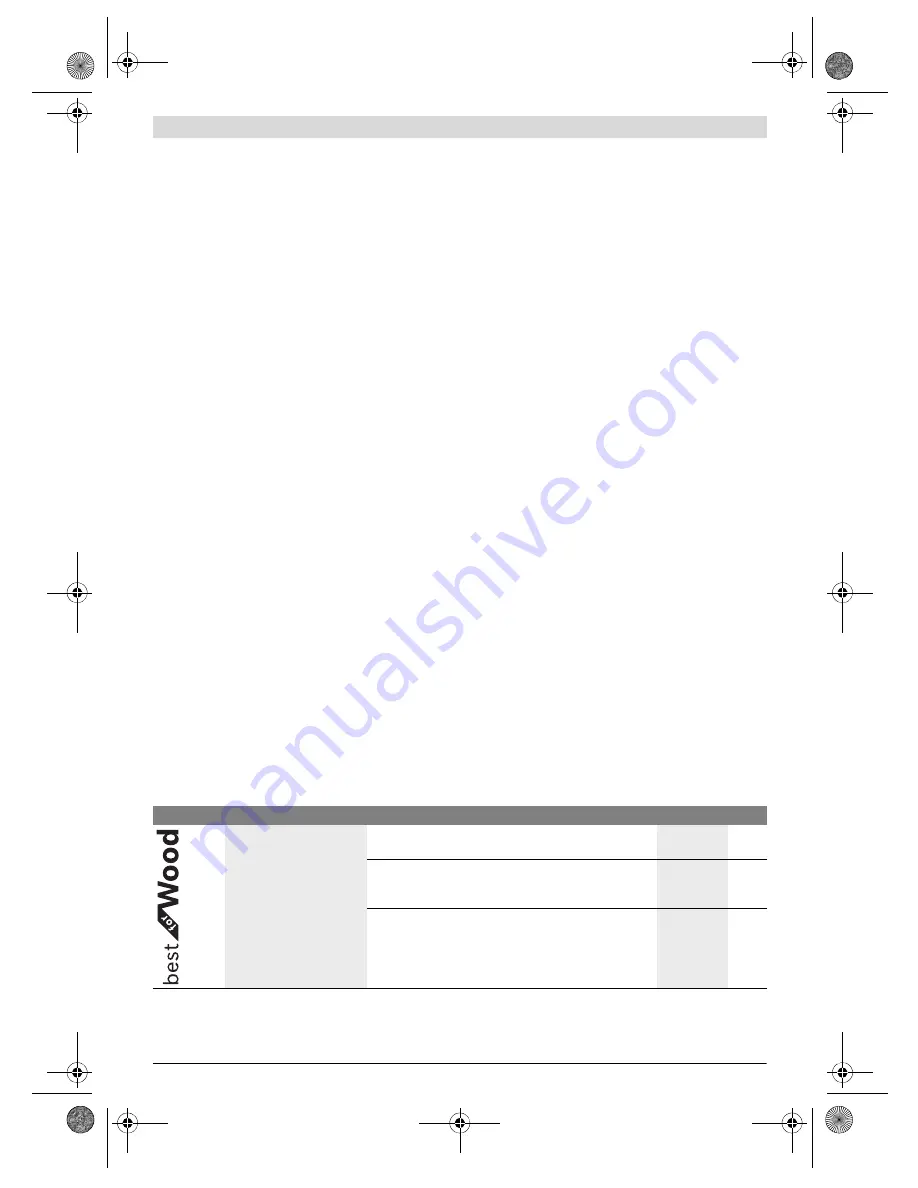

Selecting the Sanding Sheet

Depending on the material to be worked and the required rate of material removal, different sanding sheets are available:

Sanding disc Material

Application

Grain size

– All wooden materials

(e.g., hardwood, soft-

wood, chipboard, build-

ing board)

– Metal materials

For coarse-sanding, e.g. of rough, unplaned beams and

boards

coarse

40

60

For face sanding and planing small irregularities

medium

80

100

120

For finish and fine sanding of wood

fine

180

240

320

400

OBJ_BUCH-2788-001.book Page 12 Thursday, January 14, 2016 3:19 PM