Velocity controller integral time (in‐

tegral part)

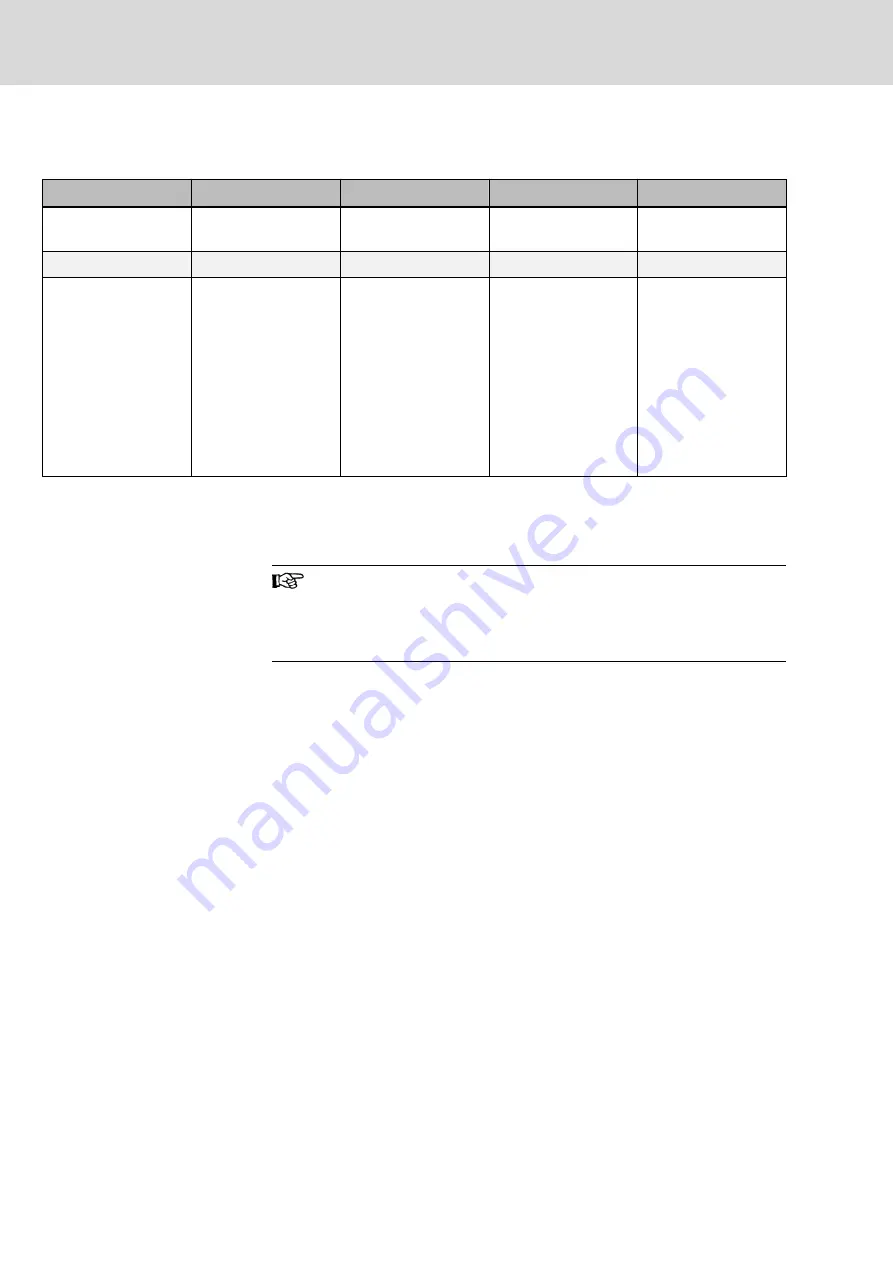

The following possibilities must be taken into account for the velocity control‐

ler integral time (integral part):

Possibility 1

Possibility 2

Possibility 3

Possibility 4

Alignment of length lin‐

ear scale and guides

ideal

not ideal

not ideal

not ideal

Integral Part

in both axes

in both axes

in one axis only

in no axis

Behaviour of the axes Since both motors fol‐

low the position com‐

mand value ideally,

there will not be a dis‐

tortion of the mechani‐

cal system

Both

axes

work

against each other un‐

til there is an equaliza‐

tion via the mechanical

coupling or until the

maximum current of

one or both drive con‐

troller(s) has been

reached and a control

effect is no longer pos‐

sible.

The axis without inte‐

gral-part permits a con‐

tinuous position offset.

The size of the position

offset depends on the

rigidity of the mechani‐

cal coupling of both ax‐

es and of the propor‐

tional gains in the posi‐

tion and velocity con‐

trol loop.

Both axes permit a

continuous position off‐

set. The size of the po‐

sition offset depends

on the proportional

gains in the position

and velocity control

loop.

Tab. 14-6:

Parameterization of the velocity controller integral time S-0-0101 for

Gantry-axes.

Optimization

The previously described procedure must be followed for optimizing the posi‐

tion and velocity loop.

Any parameter modifications that are made during the optimiza‐

tion of Gantry axes must always be made in both axes simultane‐

ously. If this is not possible, the parameter changes should be

made during optimization in smaller subsequent steps in both ax‐

es.

14.7.3

Estimating the moved mass using a velocity ramp

Often, the exact moving mass of the machine slide is not known. Determining

this mass can be made difficult by moving parts, additionally mounted parts,

etc.

The procedure explained below permits the moving axes mass to be estima‐

ted on the basis of a recorded velocity ramp. This permits, for example, the

acceleration capability of the axis to be estimated.

Preparation

This procedure requires the oscillographic recording of the following parame‐

ters:

●

S-0-0040, actual velocity value

●

S-0-0080, torque/force command value

You can either use an oscilloscope or the oscilloscope function of the drive in

conjunction with IndraWorks or NC.

Bosch Rexroth AG

DOK-MOTOR*-MCL********-PR05-EN-P

180/193

Rexroth IndraDyn L Ironless Linear Motors MCL

Commissioning, operation and maintenance

Summary of Contents for DOK-MOTOR-MCL Series

Page 14: ...Bosch Rexroth AG DOK MOTOR MCL PR05 EN P 12 193 Rexroth IndraDyn L Ironless Linear Motors MCL ...

Page 48: ...Bosch Rexroth AG DOK MOTOR MCL PR05 EN P 46 193 Rexroth IndraDyn L Ironless Linear Motors MCL ...

Page 64: ...Bosch Rexroth AG DOK MOTOR MCL PR05 EN P 62 193 Rexroth IndraDyn L Ironless Linear Motors MCL ...

Page 78: ...Bosch Rexroth AG DOK MOTOR MCL PR05 EN P 76 193 Rexroth IndraDyn L Ironless Linear Motors MCL ...

Page 84: ...Bosch Rexroth AG DOK MOTOR MCL PR05 EN P 82 193 Rexroth IndraDyn L Ironless Linear Motors MCL ...

Page 98: ...Bosch Rexroth AG DOK MOTOR MCL PR05 EN P 96 193 Rexroth IndraDyn L Ironless Linear Motors MCL ...