6 720 809 134 (2013/09)

Compress 3000 DW FII

Installation | 13

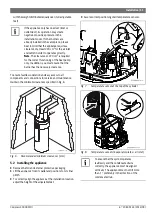

▶ Determine the nominal diameter of the room's water

installation. Please note the current water pressure and the

expected pressure loss.

▶ Carry out the water connection in accordance with the

applicable regulations. Please observe the local regulations

on DHW installations.

▶ The water pipes can be rigid or flexible. To avoid corrosion,

take into account the behaviour of the materials used in the

pipe system and the connections.

To prevent heat loss and to ensure maximum appliance

performance:

▶ Thermally isolate the water connections.

Safety valve

1)

▶ Fit the safety valve to the water inlet of the appliance.

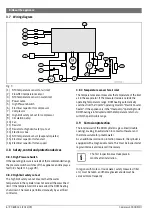

5.5 Internal indirect coil connection

2)

The appliance is equipped with an additional internal indirect

coil which enables the solar system or boiler to provide

support.

When the water temperature in the cylinder reaches 80 °C, the

control switches off the support system. This prevents damage

to the refrigerant circuit in the heat pump and stops the high

limit safety cut-out from being activated.

If the internal indirect coil is not used:

▶ Seal off the internal indirect coil's inlet and outlet apertures

with plugs.

To prevent faults occurring due to sudden

pressure fluctuations in the supply:

▶ Fit a non-return valve and a pressure

control valve to the appliance supply.

NOTICE:

Pipes can be damaged if treated

incorrectly.

▶ Do not allow pipes to become

contaminated during installation.

▶ If necessary, flush the pipes with water

prior to commissioning.

Prior to installation, thoroughly flush water

pipes as the water flow could be reduced by

contaminants and, in case of severe

contamination, be stopped completely.

▶ Fit a water filter to the water inlet.

NOTICE:

Corrosion damage to the cylinder's

connections!

If the connections are made from copper:

▶ Use an isolation fitting for the hydraulic

connection

1)

. This extends the service

life of the magnesium anode.

1) Accessory not included in standard delivery

1) Accessory not included in standard delivery

If the water inlet pressure is higher than

8 bar - 80% of the allowable maximum value

(10 bar) -, install a reducing valve. The safety

valve is activated when the water pressure

exceeds the upper limit (

Tab. 6, page 15),

allowing water to drain off. A tundish should

be provided for this purpose.

NEVER CLOSE OFF THE SAFETY VALVE

DRAIN.

Never install accessories between the safety

valve and the appliance water connection.

NOTICE:

The drain line from the safety valve must be

laid in a frost-free location. It must remain

open to the atmosphere and always be kept

in a sloped position.

2) HP270-2E1...model only

WARNING:

Risk of scalding!

Hot water can lead to severe scalding.

▶ Inform users of the danger of scalding and

always monitor the thermal disinfection

process. Install a thermostatic DHW

mixer.

Summary of Contents for Compress 3000 DW FI Series

Page 29: ...6 720 809 134 2013 09 Compress 3000 DW FII 29 Notes ...

Page 30: ...6 720 809 134 2013 09 Compress 3000 DW FII 30 Notes ...

Page 31: ...6 720 809 134 2013 09 Compress 3000 DW FII 31 Notes ...

Page 32: ...Bosch Thermotechnik GmbH Junkersstrasse 20 24 D 73249 Wernau www bosch thermotechnology com ...