English |

25

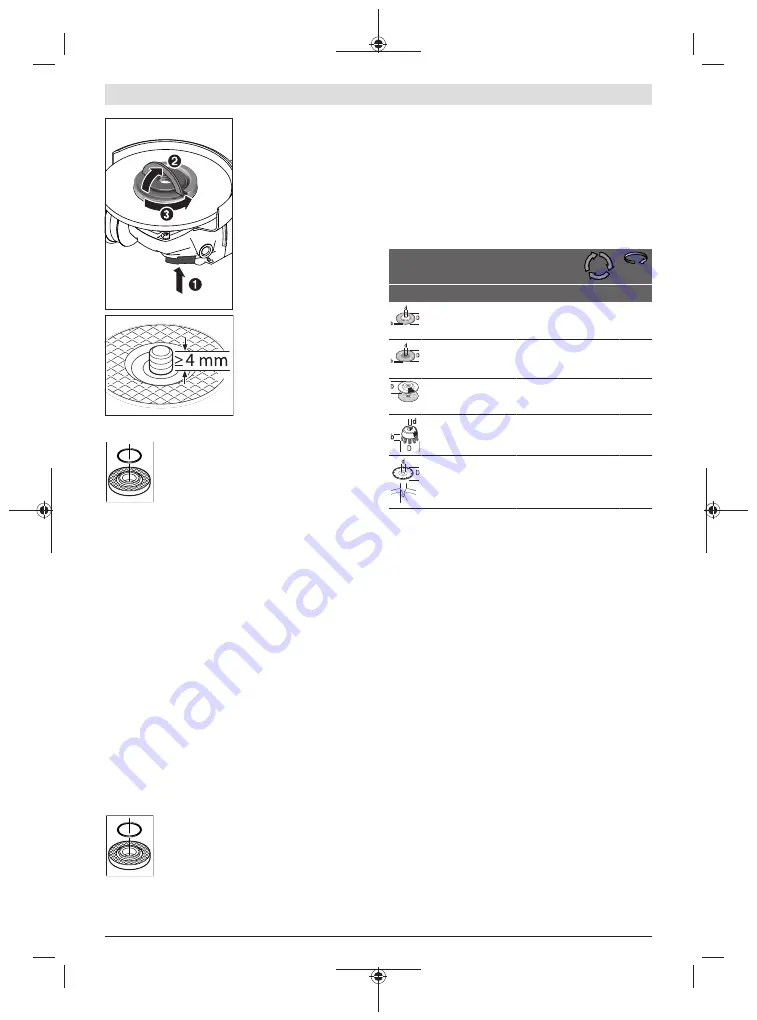

Quick-clamping nuts

(19)

that are properly secured

and not damaged can be re-

moved by hand. To do this,

fold up the bar and turn the

quick-clamping nut firmly

anticlockwise. If the quick-

clamping nut is stuck, do

not attempt to loosen it with

a tool – always use a two-

pin spanner.

After fitting the hub flange

and the grinding/cutting

disc, the free thread length

of the grinding spindle must

be

at least 4 mm

.

Ensure that the abrasive

tool is firmly seated, so that

it does not twist away from

the spindle in the runout of the power tool.

A plastic part (O-ring) is fitted around the cent-

ring collar in the hub flange

(14)

.

If the O-ring

is missing or damaged,

the hub flange

(14)

must be replaced before operation can re-

sume.

u

After fitting the abrasive tool, check that the abrasive

tool is fitted correctly and can turn freely before

switching on the power tool. Make sure that the abras-

ive tool does not brush against the protective guard or

other parts.

Assembly with Clamping Nut

(18)

Pay attention to the dimensions of the grinding tools. The

mounting hole diameter must fit the mounting flange without

play. Do not use reducers or adapters.

When using diamond cutting discs, pay attention that the

direction-of-rotation arrow on the diamond cutting disc and

the direction of rotation of the machine (see direction-of-ro-

tation arrow on the machine head) agree.

See graphics page for the mounting sequence.

To fasten the grinding/cutting disc, screw on the clamping

nut

(18)

and tighten with the two-hole spanner.

u

After fitting the abrasive tool, check that the abrasive

tool is fitted correctly and can turn freely before

switching on the power tool. Make sure that the abras-

ive tool does not brush against the protective guard or

other parts.

Mounting flange for grinding spindle M 14:

A plastic part (O-ring) is fitted around the cent-

ring collar in the mounting flange

(14)

.

If the

O-ring is missing or damaged,

the mounting

flange

(14)

must be replaced before operation

can resume.

Approved abrasive tools

You can use all the abrasive tools mentioned in these operat-

ing instructions.

The permissible speed [min

-1

] or the circumferential speed

[m/s] of the abrasive tools used must at least match the val-

ues given in the table.

It is therefore important to observe the permissible

rota-

tional/circumferential speed

on the label of the abrasive

tool.

Max. [mm]

[mm]

[°]

D

b

s

d

α

[min

-1

] [m/s]

115

125

6

6

–

–

22.2

22.2

–

–

11,500

11,500

80

80

115

125

3.2

3.2

–

–

22.2

22.2

–

–

11,500

11,500

80

80

115

125

–

–

–

–

–

–

–

–

11,500

11,500

80

80

75

30

–

M 14

–

11,500

45

α

s

115

125

6

6

10

10

22.2

22.2

> 0

> 0

11,500

11,500

80

80

Dust/Chip Extraction

Dust from materials such as lead-containing coatings, some

wood types, minerals and metal can be harmful to one’s

health. Touching or breathing-in the dust can cause allergic

reactions and/or lead to respiratory infections of the user or

bystanders.

Certain dust, such as oak or beech dust, is considered carci-

nogenic, especially in connection with wood-treatment ad-

ditives (chromate, wood preservative). Materials containing

asbestos may only be worked by specialists.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the ma-

terials to be worked.

u

Avoid dust accumulation at the workplace.

Dust can

easily ignite.

Operation

u

Do not load the power tool so heavily that it comes to a

stop.

u

Remove the battery from the power tool before carry-

ing out work on the power tool (e.g. maintenance,

changing tool, etc.). The battery should also be re-

moved for transport and storage.

There is risk of injury

from unintentionally pressing the on/off switch.

Bosch Power Tools

1 609 92A 75F | (15.02.2022)