PARTS LIST

The quantity may be different from the parts listed

because some parts are pre-assembled on the unit.

Page 6

ITEM#

DESCRIPTION

QTY

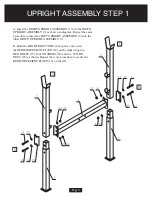

1

Upright(Right)

1

2

Upright(Left)

1

3

Down Upright

2

4

Rear Cross Tube

1

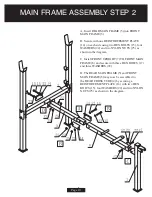

5

Rear Main Frame

1

6

Front Main Frame

1

7

Front Upright

1

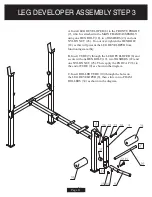

8

Leg Developer

1

9

Tube

1

10

Roller Tube

1

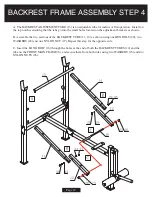

11

Backrest Tube (Long)

2

12

Backrest Tube (Short)

2

13

Backrest Adjustment Tube

1

14

Reinforcement Plate

5

15

5/16" X 2-3/16" Hex Head Bolt

8

16

3/8" X 6-7/8" Bolt

1

17

5/16" X 5/8" Hex Head Bolt

3

18

3/8" X 2-3/8" Hex Head Bolt

1

19

5/16" X 1-3/4" Hex Head Bolt

1

20

M6X35 Hex Head Bolt

8

21

M6X15 Hex Head Bolt

2

22

φ8.5Xφ17X1.5t Washer

21

23

φ10.5X

φ

20X1.5t Washer

4