3

Requirements Of Your System:

IMPORTANT!

Read before unpacking or using this product!

For the TOWER of POWER

tm

control system to function properly, your brewing system must meet

some basic requirements. If your system is unable to meet these requirements please contact your

RETAILER for guidance. We cannot guarantee the performance of the product if these basic

minimums are not met.

Hot liquor tanks perform well on nearly any system that can maintain a moderate flame. Mash Tuns require

a couple basic performance parameters to be met for proper performance.

Important!

Do not use or install the TOWER of POWER

tm

equipment until you verify that your equipment is

capable of the requirements below. If you are using Blichmann Engineering BoilerMaker

tm

mash tun with our

false bottom, and a TopTier

tm

burner you will not have equipment limitations. However, it is still important

that you verify that your crush will allow adequate wort flow! Most stuck mashes are caused by too fine of a

crush. It is also expected that

Your mashing system must have the capability to continuously recirculate your wort using a pump for the

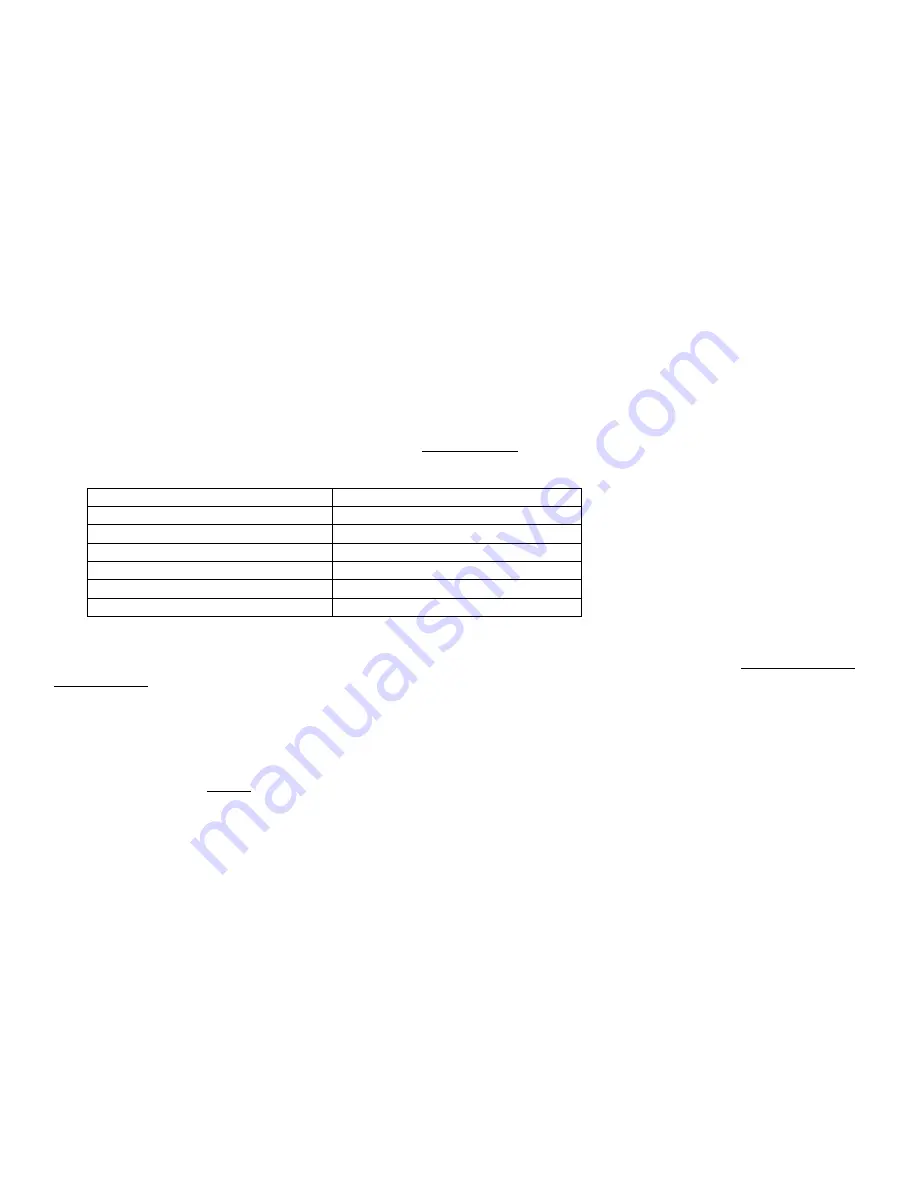

duration of the mash without sticking. The flow rates in the chart below are minimum values.

Finished Batch Size gal (L)

Min Flow GPM (LPM)

5 (19)

0.5 (2.8)

10 (38)

0.75 (3.8)

15 (57)

1.25 (4.75)

20 (76)

1.5 (5.7)

32 (121)

2.25 (8.5)

Important:

Grain bed flow rates are highly dependent on crush quality. Move to a coarser crush if you are

not able to flow at the above rates. It is also recommended that you allow a 10 min dough-in prior to turning

on the pump to allow the air to purge from the grain and for the grain to fully absorb the water.

Burner Requirement:

Your burner must be capable of operating well at low power settings. If you cannot

maintain a flame at about half power your system stability will suffer. Specifically, you should be able to

reduce your heat to achieve an average heating rate of 1.5 F/min or less. To do this, recirculate your wort at

the above rates or faster (use a stop watch and known volume to measure flow rate). Then apply heat on your

burner at the lowest stable level. If over a 20-30 min period the increase in wort temperature divided by the

time is at or below 1.5 F/min you have met this requirement.

Fuel Supply:

The solenoid valve supplied is suitable for up to 25 PSI propane regulators and residential

natural gas. Fuel flow rate through this valve is adequate to power Blichmann Engineering TopTier

tm

burners

on both fuels, however, other burners may need a larger solenoid valve (not included). Do NOT install a

solenoid valve that draws over 2A at 120V including inrush or you may damage the ignition start relay which

is NOT a warrantable failure.