3

Installation, Operation and Maintenance Manual

MAN 571_EAC Rev. 1

September 2020

General Warnings

Section 1: General Warnings

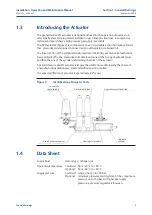

The GPO actuator (Figure 2) is composed of one or two double action hydraulic cylinders

that, pressurized, determines the linear motion of the piston contained in it.

The linear motion of the piston is transformed into rotation by a scotch yoke mechanism.

Gas sampled by the line, pressurizes oil contained in one of the two gas-hydraulic tanks

and then the one of the cylinder determining the drive of the actuator.

A peculiar feature of GPO actuator is its great flexibility of use obtained by the choice of

a manufacturing solution easy, solid and without parts in motion.

The expected lifetime of actuator is approximately 25 years .

Figure 2

Identification of Actuator Parts

1.3

Introducing the Actuator

The gas hydraulic GPO actuator is designed and used for the operation of quarter-turn

valves (ball valves and plug valves) installed on gas transportation lines, in compressor

stations and everywhere a high pressure gas supply is available.

Hydraulic manual override

Gas-hydraulic tanks

Flow-regulator valves

Pneumatic

control group

Scotch yoke mechanism

Hydraulic

cylinder

1.4

Data Sheet

Supply fluid

Natural gas / nitrogen /air

Operating temperature Standard: from –20 °C to +80 °C

Optional: from –60 °C to +80 °C

Supply pressure

Standard: ranging from 7 to 100 bar.

Optional: minimum pressures starting from 3,5 bar, maximum

pressure up to 160 bar. For higher gas supply

pressure, a pressure regulator is foreseen.