17

Installation, Operation and Maintenance Manual

MAN616_EAC Rev. 5

July 2020

Section 3: Operation and Use

Operation and Use

Section 3: Operation and Use

3.1

Operation Description

The actuator is operated by:

1.

Pressurized motor fluid.

2.

Elastic return of compression helicoidally spring.

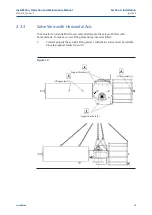

In the first case the alimentation fluid pressurizes a chamber of the cylinder and

compresses the spring (Figure 13); this determines the linear motion of the piston

and the consequent rotation motion of the scotch yoke mechanism to which valve stem

is coupled.

The fluid contained in the other chamber is discharged through the return line.

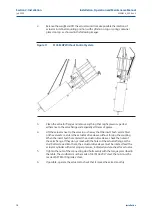

In the second case, cutting off or in case of lack of pressure to the cylinder and

to the pilot of the fast discharge valve, the opening of the latter is determined,

the fast discharge of motor fluid, the quick extension of the spring and the consequent

fast operation of the actuator. The motor fluid going out from one chamber of the cylinder

partially returns in the other chamber and partially flows through the discharge line.

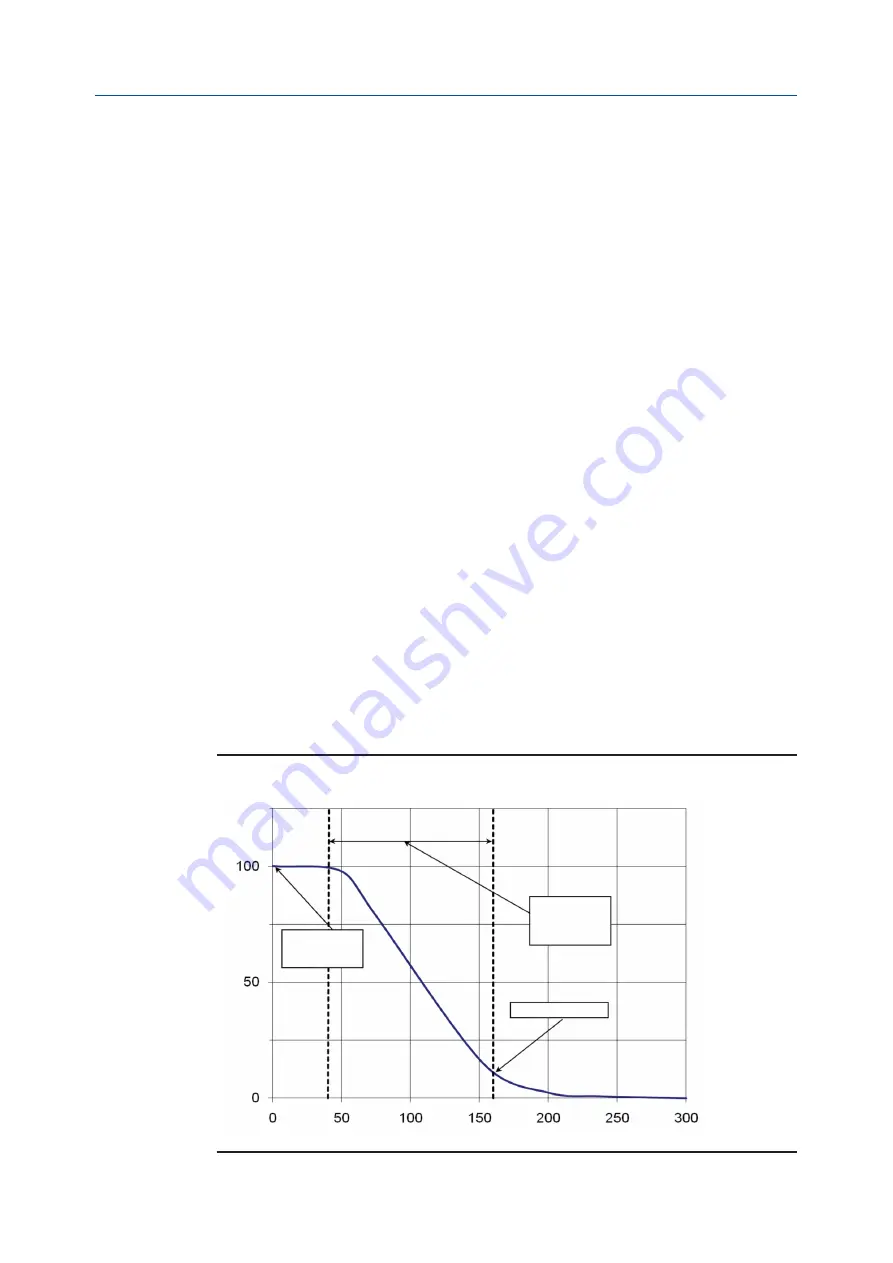

The last part of the cylinder stroke is strongly slowed down by a damper with 2 by-pass

system that throttles the outlet of the motor fluid. Figure 12 shows the diagram angular

stroke/time. By-pass action must be regulate to make more slowly the last part of cylinder

stroke (see Section 3.4.1).

The power and control systems are supplied on specific customer demand.

For the relevant information please refer to the specific documentation supplied.

Angular stroke %

Time (ms)

Quick operation

signal

Quick operation

time

Damper action

Figure 12

Angular Stroke/Quick Operation Time Diagram