11

Problem

Possible Cause

Remedy

Cabinet not running and / or no

1-2-3 controller display

Circuit breaker tripped

Reset circuit breaker (make sure circuit breakers show red indicators

for “ON” position)

Power cord unplugged

Plug in power cord

Main power supply turned “OFF”

Turn main power supply “ON”

Improper voltage supplied to cabinet

Supply correct voltage (do not use extension cords or put other

equipment on circuit etc)

Cabinet in defrost cycle

Allow defrost cycle to finish

Cabinet not pre-chilled prior to placing hot

product load

Remove product load and pre-chill cabinet for approximately 30

minutes (only applies to cabinets that do not stay on all the time)

Condensing unit on cabinet runs

for prolonged period or

continuously

Excessive amount of warm product

loaded in cabinet

Allow adequate time for product to cool down

Whole product loads placed in cabinet

Portion product load(s)

Improper use of “Soft Chill” mode

Use “Soft Chill” for delicate and less dense product loads only

Prolonged door opening or door ajar

Make sure door is closed when not in use. Avoid prolonged door

openings

Door gasket not sealing properly

Check gasket condition. Adjust door or replace gasket

Dirty condenser coil

Clean the condenser coil

Improper air flow around condensing unit

Ensure adequate air space, relocate away from heat generating

equipment, direct sunlight, or direct path of air conditioning or heating

ducts

Evaporator coil blocked with ice

Turn unit off and allow coil to defrost or manually force defrost (while

cabinet is “ON”, press and hold

&

button for manual defrost)

Cabinet temperature too high

Poor air circulation in cabinet

Move product load away from fan(s)

Excessive amount of warm product

loaded in cabinet

Allow adequate time for product to cool down

Prolonged door openings or door(s) ajar

Make sure door(s) are closed when not in use. Avoid prolonged door

openings

Dirty condenser coil

Clean the condenser coil

Insufficient clearance around cabinet or

excessively high ambient temperature

Ensure adequate air space, relocate away from heat generating

equipment (ovens, fryers etc) and out of direct sunlight

Evaporator coil blocked with ice

Turn unit off and allow coil to defrost or manually force defrost (while

cabinet is “ON”, press and hold

&

button for manual defrost)

Cabinet is noisy

Part(s) loose

Locate and tighten loose part(s)

Product taking to long to pull-down

Product load covered

Uncover product or try to use metal pans. Refer to Page 3 or “The

Guide to Cook Chill”

Improper use of “Soft Chill” mode

Use “Hard Chill” for product loads that are of great density

Compressor will not start hums

and trips circuit breaker

Dirty condenser coil

Clean the condenser coil

Excessive heat generated from

equipment nearby

Relocate cabinet, or adjacent heat generating equipment

Voltage to cabinet too high or too low

Check and correct supply voltage

Door won’t close tight

Cabinet is not level

Level cabinet by adjusting casters or legs. Shim casters or legs if

necessary

Water or ice at bottom of cabinet

Product load too hot

Cool down product load before placing into cabinet (Note: product load

should be no higher than 160°F)

Error code displayed

Loose or defective food probe /

thermocouple. Main power failure

Press

(cancel) button to stop alarm sound off

Thermal printer paper not

feeding or printing tickets

Thermal printer paper jamming, not

straight or properly seated. Printer paper

spool is finished

Reload paper

BEFORE CALLING SERVICE GUIDE FOR WBC COMMON PROBLEMS

CAUTION: Disconnect power supply prior to attempting any service!

Summary of Contents for Williams WBC110

Page 12: ...12 by OPERATING ENGINEERS MANUAL for WILLIAMS DATA LOGGER W D L with PRINTER MODULE...

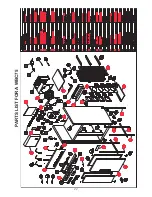

Page 20: ...20 PARTS LIST FOR A WBC35...

Page 21: ...21 PARTS LIST FOR A WBC60...

Page 22: ...22 PARTS LIST FOR A WBC75...

Page 23: ...23 PARTS LIST FOR A WBC110...

Page 24: ...24 PARTS LIST FOR A WMBC175 220 350 CONTROLLER WITH POD PRINTER...

Page 25: ...25 PARTS LIST FOR A WMBC175 220 350 PANEL LAYOUT...

Page 26: ...26 PARTS LIST FOR A WMBC175 220 350 EQUIPMENT...

Page 27: ...27 PARTS LIST FOR A WMBC175 220 350 POD EQUIPMENT...

Page 28: ...28 PARTS LIST FOR A WMBC175 220 350 PANEL LAYOUT...

Page 29: ...29 PARTS LIST FOR A WMBC350 EQUIPMENT...

Page 30: ...30 PARTS LIST FOR A WMBC480 660 PANEL LAYOUT...

Page 31: ...31 PARTS LIST FOR A WMBC480 660 CONTROL PANEL WITH PRINTER POD...

Page 32: ...32 PARTS LIST FOR A WMBC480 EQUIPMENT LAYOUT...

Page 33: ...33 PARTS LIST FOR A WMBC660 EQUIPMENT LAYOUT...

Page 34: ...34 PARTS LIST FOR A WMBC480 660 POD EQUIPMENT...

Page 35: ...35 PARTS LIST FOR A WMBC480 660 PANEL LAYOUT...

Page 49: ...49...

Page 50: ...50...

Page 51: ...51...