©2019 BERNINA of America. Permission granted to copy and distribute in original form only. Content may not be altered or used in any other form or under any other branding.

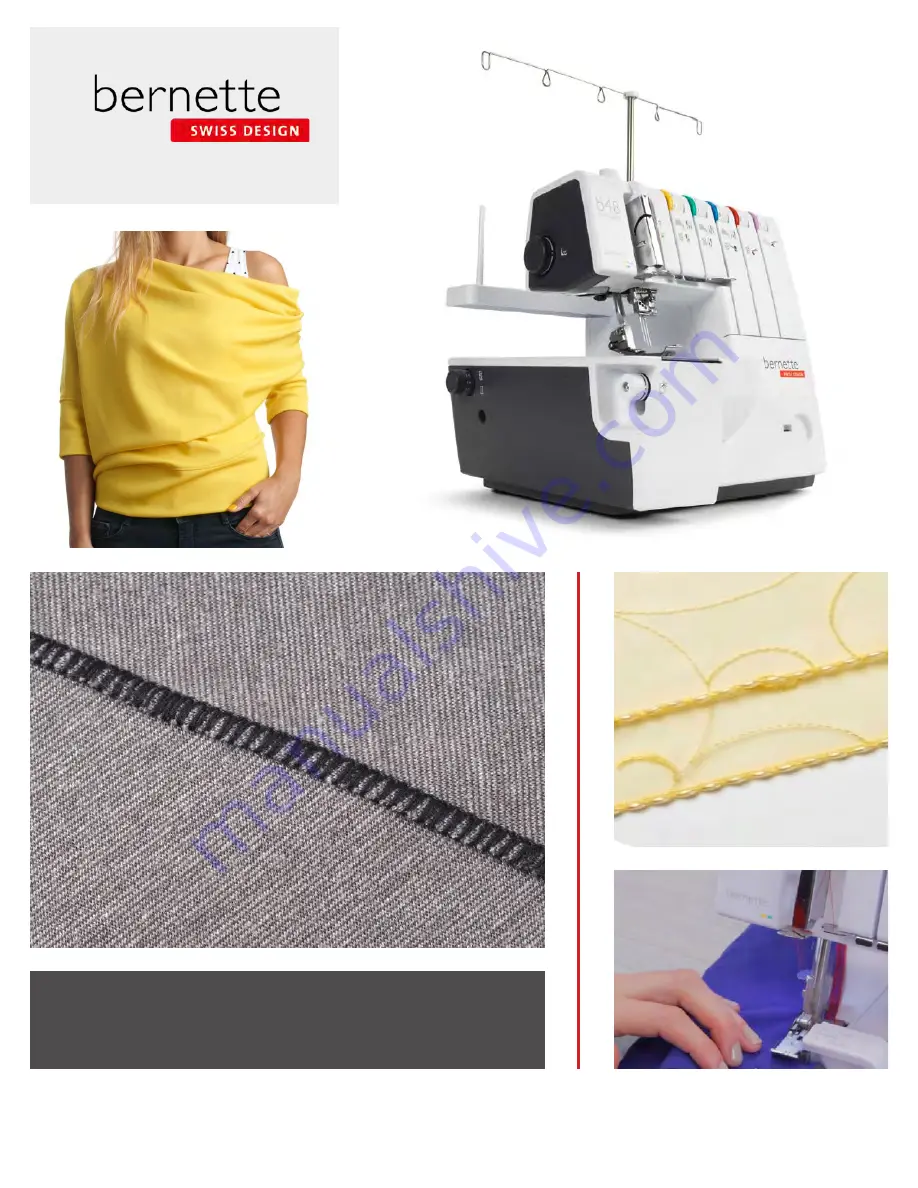

For bernet te Overlockers: b4 4, b4 8

WORKBOOK #1 – BASIC SERGER USE

OVERLOC KER

M A S T E R Y

B O O K

S E R I E S