33

LIFt oPERAtIoN SAFEty

• DAILY

inspect your lift. Never operate if it malfunctions

or if it has broken or damaged parts. Use only qualified lift

service personnel and genuine BendPak parts to make

repairs.

• THOROUGHLY

train all employees in use and care of

lift, using manufacturer’s instructions and “Lifting It Right”

and “Safety Tips” supplied with the lift.

• NEVER

allow unauthorized or untrained persons to

position vehicle or operate lift.

• PROHIBIT

unauthorized persons from being in shop

area while lift is in use.

• DO NOT

permit anyone on lift or inside vehicle when it

is either being raised or lowered.

• ALWAYS

keep area around lift free of tools, debris,

grease and oil.

• NEVER

overload lift. Capacity of lift is shown on

nameplate affixed to the lift.

• DO NOT

stand in front of the vehicle while it is being

positioned in lift bay.

• DO NOT

hit or run over lift arms or adapters. This could

damage lift or vehicle. Before driving vehicle into lift bay,

position arms and adapters to provide unobstructed

entrance onto lift.

• ALWAYS

load vehicle on lift carefully. Position the lift

adapters to contact at the vehicle manufacturer’s

recommended lift points. Raise lift until adapters contact

vehicle. Check adapters for secure contact with vehicle.

Raise lift to desired working height. (See Fig.19.1)

• DO NOT

block open or override self-closing lift controls;

they are designed to return to the “Off” or Neutral position

when released.

• DO NOT

remove or disable arm restraints.

• ALWAYS

remain clear of lift when raising or lowering

vehicles.

• ALWAYS

use safety stands when removing or installing

heavy components.

• DO NOT

go under raised vehicle if safety locks are not

engaged.

• NEVER LEAVE LIFt IN ELEVAtED CoNDItIoN

unless all Safety Locks are engaged.

• AVOID

excessive rocking of vehicle while on lift.

• ALWAYS CLEAR AREA

if vehicle is in danger of falling.

When lowering the lift PAy CAREFuL AttENtIoN

that all personnel and objects are kept clear.

ALWAyS keep a visual line of site on the lift At ALL

tIMES. ALWAyS make sure that ALL LoCKS are

disengaged. If one of the locks inadvertently locks

on descent the lift and/or vehicle may disrupt

causing personal injury or death,

• ALWAYS REMOVE

tool trays, stands, etc. before

lowering lift.

• ALWAYS RELEASE

safety locks before attempting to

lower lift.

•

ALWAyS PoSItIoN

the lift arms and adapters to

provide an unobstructed exit before removing vehicle

from lift area.

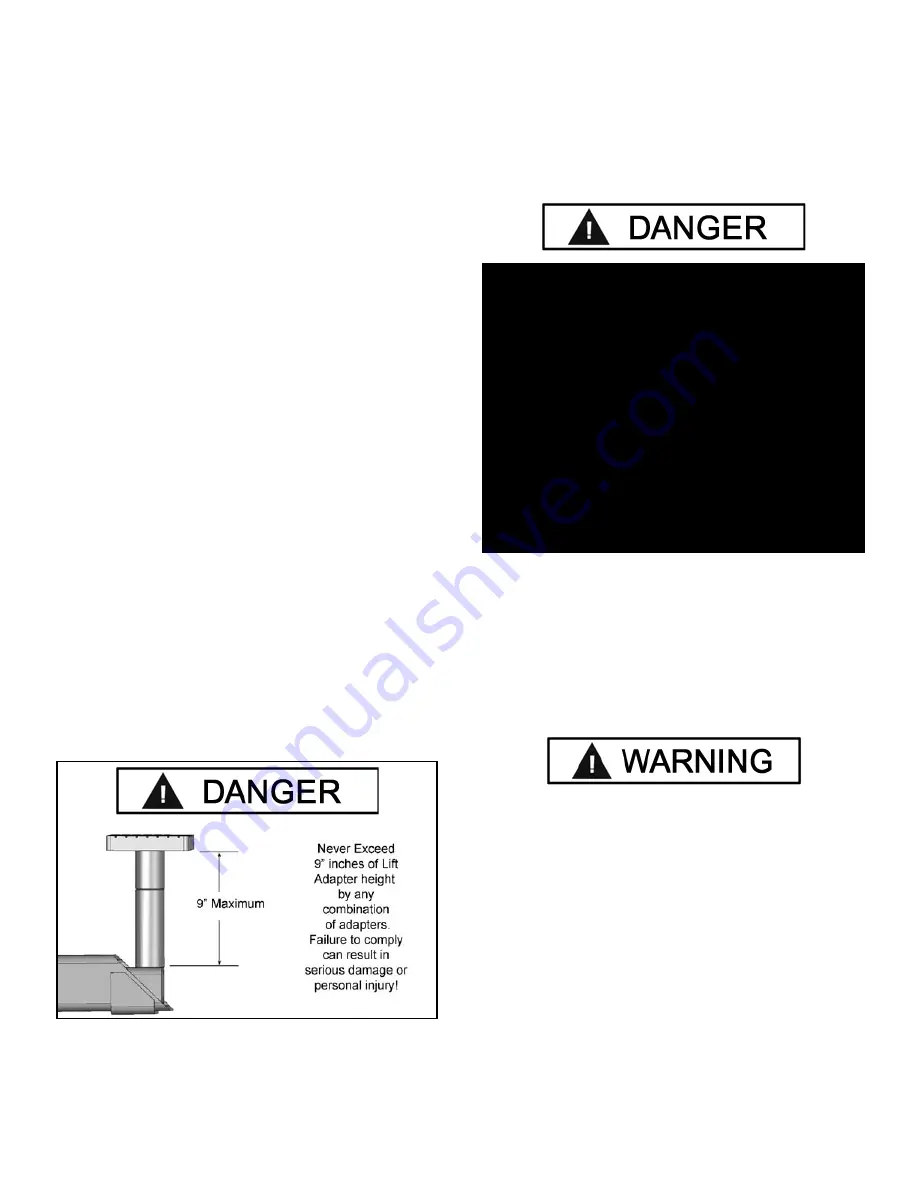

DANGER!

VISuALLy CoNFIRM tHAt ALL PRIMARy

SAFEty LoCKS ARE ENGAGED BEFoRE

ENtERING WoRK AREA.

Suspension components us on this lift are

intended to raise and lower lift only and are

not meant to be load holding devices.

Remain clear of elevated lift unless visual

confirmation is made that all primary

safety locks are fully engaged and the lift is

LOWERED onto the safety locks, Refer to

installation /operation manual for proper safety

lock procedures and /or further instruction.

Fig. 19.1

Summary of Contents for XpR-10AC

Page 23: ...23 23 ...

Page 26: ...26 ...

Page 30: ...30 30 OPTIONAL EQUIPMENT INSTALLATION ...

Page 40: ...40 40 ...

Page 41: ...41 41 ...

Page 49: ...49 49 ...