Product overview

CP69xx

14

Version: 3.0

3.3

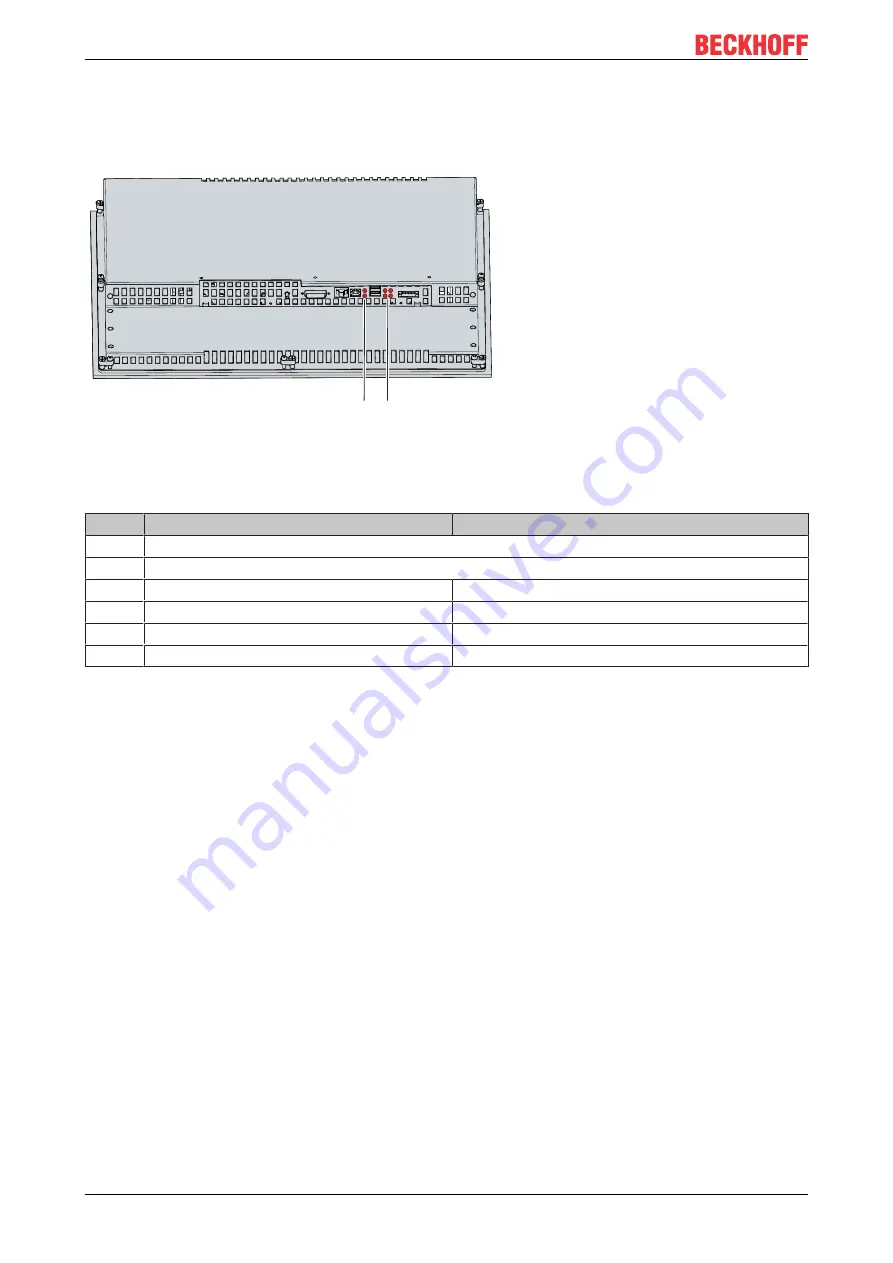

Status LEDs

The Control Panel has six status LEDs. They are located on the rear side in the connection section of the

panel (see fig. 8).

Fig. 8: CP69xx_Status LEDs

The LEDs have the following meanings:

Table 7: LED functions

LED

Name

Meaning

1

No function

2

No function

3

USB 1

USB 1 interface in operation

4

USB 2

USB 2 interface in operation

5

Power Good

Input voltage OK

6

24 V in

Power supply established