2

USER MANUAL

CAUTION: READ, UNDERSTAND AND FOLLOW ALL SAFETY RULES AND OPERATING INSTRUCTIONS IN

THIS MANUAL BEFORE USING THIS PRODUCT.

SAVE THESE INSTRUCTIONS – READ ALL INSTRUCTIONS!

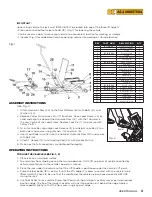

PURGING AIR FROM HYDRAULIC SYSTEM

SAFETY INSTRUCTIONS

PRODUCT DESCRIPTION AND FEATURES

• Failure to comply with information in this manual or to heed product warning labels may result in

personal injury or property damage.

• Study, understand and follow all the instructions before operating this device.

• This Jack is rated for a maximum of 1500 pounds. DO NOT exceed the rated capacity. Overloading may

cause damage to the jack and cause it to fail.

• ONLY use jack on a hard level surface that is capable of supporting the vehicle.

• Lift only on areas of vehicle as specified by the vehicle manufacturer.

• ALWAYS use the Height Lock Bar (2) when the vehicle is raised to prevent the vehicle from dropping

accidentally.

• ALWAYS lower the vehicle to the lowest possible jack position BEFORE attempting to dolly or move it.

• DO NOT make any alterations to this product.

• ALWAYS inspect the jack before each use.

• DO NOT use if leaking fluid and/or broken, bent, cracked or otherwise damaged parts are noted.

• Immediately after raising the vehicle, ensure that the Height Lock Bar is engaged.

• ALWAYS wear safety glasses when operating this product.

NEVER place yourself under or in a position around a raised vehicle where if it came

loose from the jack and fell off of the jack, it could cause serious bodily injury!

During shipment and handling, air may get trapped in the hydraulic System which can

interfere with the jack‘s lifting performance. Follow these Steps to release the air:

• Open the release valve by pressing down on the release pedal (19) (see Fig. 1).

• Remove the Hydraulic Ram (see Fig. 1).

• Pump the foot pedal (18) (see Fig. 1 and 2) 6 to 8 times to release any pressurized air that may be

trapped in the oil reservoir (hydraulic system).

• Be sure oil level is just below the threads in the hydraulic ram hole. If oil needs to be added follow the

instructions on page 4.

• Replace and tighten Hydraulic Ram.

This jack (see Fig. 1) has special built-in features that make it ideal for performing minor repairs, oil

changes, cleanups and more. These features include:

• 680 kg load capacity to lift most motorcycles and ATV‘s.

• A fast-action hydraulic pump with foot pedal (18) (see Fig.1, 2) for easy lifting from SVsto 37 cm above

front of jack base.

• 3-position Height Lock Bar provides positive locking at three lift heights: 20 cm, 28 cm and 33 cm (see

Fig. 1).