NE214

34

www.baumer.com

The user is responsible for ensuring that a switching load of 8A /

150 VA (W) is not exceeded in the event of a fault. Internal spark

suppression by means of two zinc oxide varistors (275 V). The output

relays of the instrument (1 relay or several) may only be disengaged

in total

5 x per minute at the most. Admissible clicks

according

to interference suppression standard EN 61000-6-4 for the industrial

sector. In case of a higher switching rate, the operator must take

care of interference suppression on the spot and under his own

responsibility by observing the load to be switched.

➜

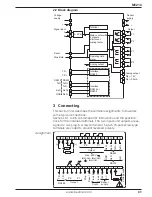

Assign terminals 20, 21, 22 and 23, 24, 25 accordingly.

3.4 Assigning the signal inputs

Terminals 6 to 9 are signal inputs. Terminals 6 (track A) and 7 (track B)

are signal inputs for the counter. The type of signal and signal logic

are programmed in lines 25 and 28. Terminal 8 serves as the reset

input. The counter is reset by way of an external signal (signal width

> 30 ms). Terminal 9 (stop) is programmed for stop/hold/operating

hours (line 31).

Input resistance

ca. 3 kOhm

Max. input level

±40 VAC

Max. frequency F1

10 kHz

Min. attenuation

3 kHz

➜

Assign terminals 6 to 9 accordingly.

For suitable pulse generators, see the Encoder Catalogue.

3.5 Connecting the sensor supply

Connect the sensor supply at terminals 4 and 5.

Do not use the sensor supply to supply non-earthed inductive or

capacitive loads.

The sensor supply is not short-circuit proof.

Terminal

Voltage

Max. residual

ripple

Max. permissible

current

4

0 V

–

–

5

+24 VDC

+10 %/-50 %

depending on load

100 mA