G 120 II V

Page 112

1st Edition, Rev. 0 Chg. 2

High levels of CO

2

are another cause of breathing air to become contaminated. CO

2

limits are 1,000 ppm.

and most fresh air already contains about 330 ppm. A number of people inside poorly ventilated rooms

can easily bring the CO

2

levels up to 600 ppm or more. If high levels of CO

2

are normally present at the

compressor intake, increased ventilation may alleviate the problem. Moving the intake to an outside loca-

tion is another viable solution.

8.2.3.2

Outside Air Source

Moving a compressor’s air intake to an outside location can improve the quality of the processed air and

increase the lifespan of the purification filters. Before moving a compressor’s intake to an outside loca-

tion take into account the changing conditions that may occur around where the air intake will be. Other

exhausts vents, vehicle or machinery exhausts and fumes may contaminate the air in the area you wish to

place your air intake. Air samples can be taken and submitted for laboratory analysis if there are any

doubts in the air quality.

If your air source is located outside, inspect the inlet piping regularly to ensure nothing has obstructed or

contaminated the air that is being taken in.

8.2.4

Compressor Intake Piping

It is best to keep intake piping as short and straight as possible. Minimum height should be 8 - 10 ft. The

end of the piping should point downward to avoid precipitation. Nothing should be allowed to restrict the

air flow.

Breathing air can often fail to meet CGA standards, unless procedures are taken to provide a fresh air

source for the compressor intake. The inlet source should be the cleanest ambient air available. Factors to

consider when installing compressor intake piping in a building are the length of pipe, the diameter, and

the number of 90° bends. All intake pipes must have a bug screen on the inlet end to prevent birds, bugs,

or large debris from entering the inlet system. A gooseneck end or water trap on the pipe will prevent

water from entering the compressor system. See the following table for recommended inlet pipe diameter.

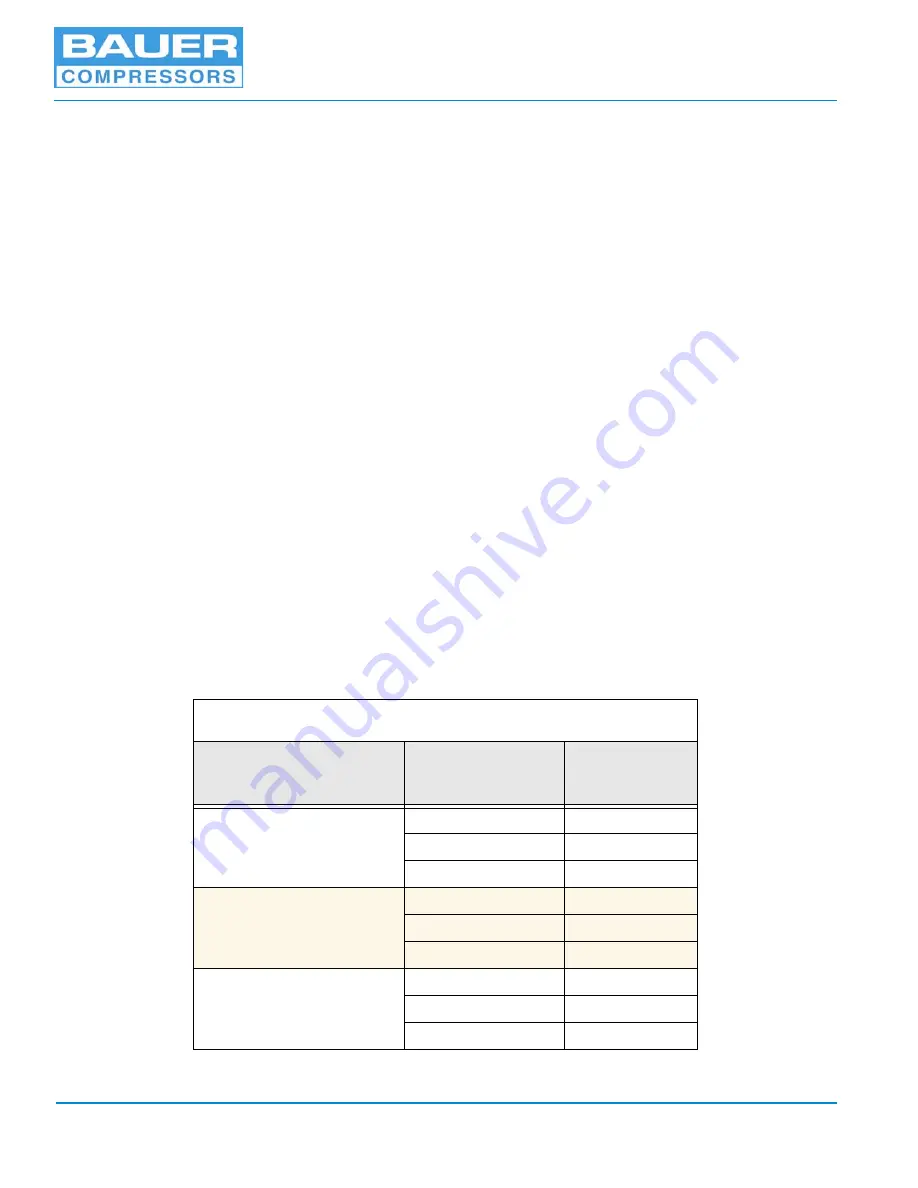

Guideline for Intake Piping with Max. Four 90° bends

Inlet Capacity

Distance

Pipe

Diameter

a

a. Add 1” of pipe diameter if the number of 90° bends exceeds four

≤

13 SCFM

≤

50 ft

2”

50 - 100 ft

3”

100 - 150 ft

4”

13 - 30 SCFM

≤

50 ft

3”

50 - 100 ft

4”

100 - 150 ft

5”

30 - 50 SCFM

≤

50 ft

4”

50 - 100 ft

5”

100 - 150 ft

6”