Installation and Maintenance Manual: Shoe Sorter

_____________________________________________________________________________________________

Installation and Mai ntenance Manual: Shoe Sorter

Published October 2019

Rev.A1

42

7.4

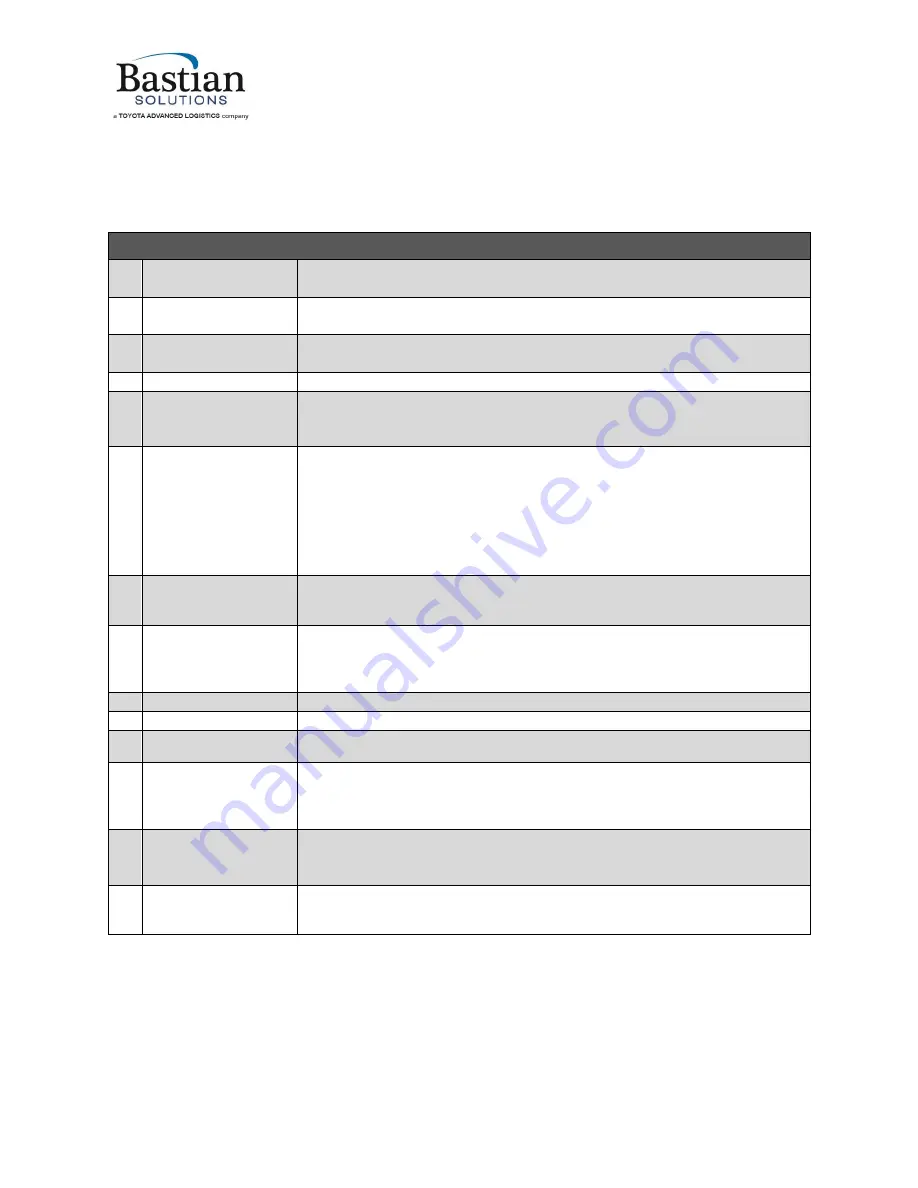

Recommended Preventative Maintenance Schedule

Table 3-Recommended Preventative Maintenance Schedule

✓

INTERVAL

DESCRIPTION OF CHECK

Before each startup

Make sure the conveyor is clear of foreign objects and all personnel are safely

away from moving parts.

Once per shift

Visual and auditory inspection to check for oil leakages, hardware security, or any

unusual noise that may indicate there is a problem with the equipment.

Daily

Inspect all the photoeyes and proximity switches to make sure they are secure

and properly aligned.

Weekly

Check for product build-up around and on slats. Clean if necessary.

Weekly

Visually inspect the slats for damage, unseated spring clips, excessive

spillage/residue or other problems (additional inspections as needed based on

maintenance history).

Weekly

Refill the oiler (as needed) and monitor for correct oil consumption.

1.

Ensure the oiler is dispensing oil at regular intervals (if the rate of usage

drops significantly, it may indicate a clog or obstruction) and refill when

necessary.

2.

Refill with SAE 30 mineral oil or SAE 85W gear oil (ISO 100), for operation

between 40°F and 100°F.

a.

Consult ZiPline for operation at temperatures outside these limits.

Monthly or 300 hours

Clean the pin sensor windows in the divert switches. (Additional cleaning to be

performed as needed if sensor faults are recorded.)

Monthly or 300 hours

Verify free movement of the divert switch gate, verify the lead-ins and switch

gate are undamaged, and clean out any accumulated debris or dirt in and around

the switch gate mechanism and sliding surfaces.

Monthly or 300 hours

Clean the surfaces of all slats to allow free motion of shoes.

Monthly or 300 hours

Check for loose bolts, nuts, fittings, and sensors. Tighten if necessary.

Monthly or 300 hours

Remove any accumulated debris on the gearbox or motor housing.

Monthly or 300 hours

Check the proper functioning of all proximity switches and photoeyes. Secure all

mounting brackets, clean the lenses and reflectors, and replace any that are

defective.

After first 24 hours,

and every 2 months or

500 hours thereafter

Check torque of all set screws (see ABB Instruction Manual for DODGE® Bearings

for appropriate torque values).

3 months or 1,000

hours

Regrease all bearings with No. 2 lithium complex base grease (see ABB

Instruction Manual for DODGE® Bearings for detailed lubrication instructions).