9170700990 Rev D

BE1-60 Installation

4-1

SECTION 4

•

INSTALLATION

INTRODUCTION

BE1-60 relays are shipped in sturdy cartons to prevent damage during transit. Upon receipt of a relay,

check the model and style number against the requisition and packing list to see that they agree. Inspect

the relay for shipping damage. If there is evidence of damage, file a claim with the carrier, and notify the

regional sales office or Basler Electric.

If the relay will not be installed immediately, place the relay in its original shipping carton and store in a

moisture- and dust-free environment.

RELAY OPERATING GUIDELINES AND PRECAUTIONS

Before installing or operating the relay, not the following guidelines and precautions.

•

For proper current operated target operation, a minimum current of 200 milliamperes must flow

through the output trip circuit.

•

If a wiring insulation test is required, remove the connection plugs and withdraw the relay from its

case.

MOUNTING

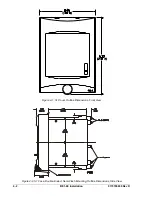

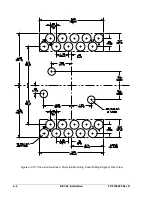

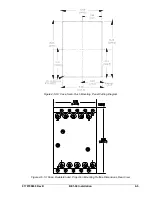

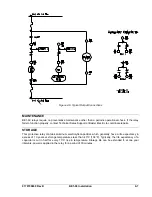

Because the relay is of solid-state design, it may be mounted at any convenient angle. Relay case

dimension drawings and panel cutting and drilling diagrams are provided in Figures 4-1 through 4-6.

CAUTION

When the connection plugs are removed, the relay is disconnected from the

operating circuit and will not provide system protection. Always be sure that

external operating (monitored) conditions are stable before removing a relay for

inspection, test, or service.

NOTE

Be sure that the relay is hard-wired to earth ground with no smaller than 12 AWG

copper wire attached to the ground terminal on the rear of the case. When the

relay is configured in a system with other devices, it is recommended to use a

separate lead to the ground bus from each device.

Summary of Contents for BE1-60

Page 1: ...INSTRUCTION MANUAL FOR VOLTAGE BALANCE RELAY BE1 60 Publication 9170700990 Revision D 09 07...

Page 2: ......

Page 6: ...iv BE1 60 Introduction 9170700990 Rev D This page intentionally left blank...

Page 8: ...vi BE1 60 Introduction 9170700990 Rev D This page intentionally left blank...

Page 12: ...1 4 BE1 60 General Information 9170700990 Rev D Figure 1 3 BE1 60 Style Chart...

Page 20: ...3 4 BE1 60 Functional Description 9170700990 Rev D This page intentionally left blank...

Page 28: ...4 8 BE1 60 Installation 9170700990 Rev D This page intentionally left blank...

Page 30: ...5 2 BE1 60 Testing 9170700990 Rev D This page intentionally left blank...