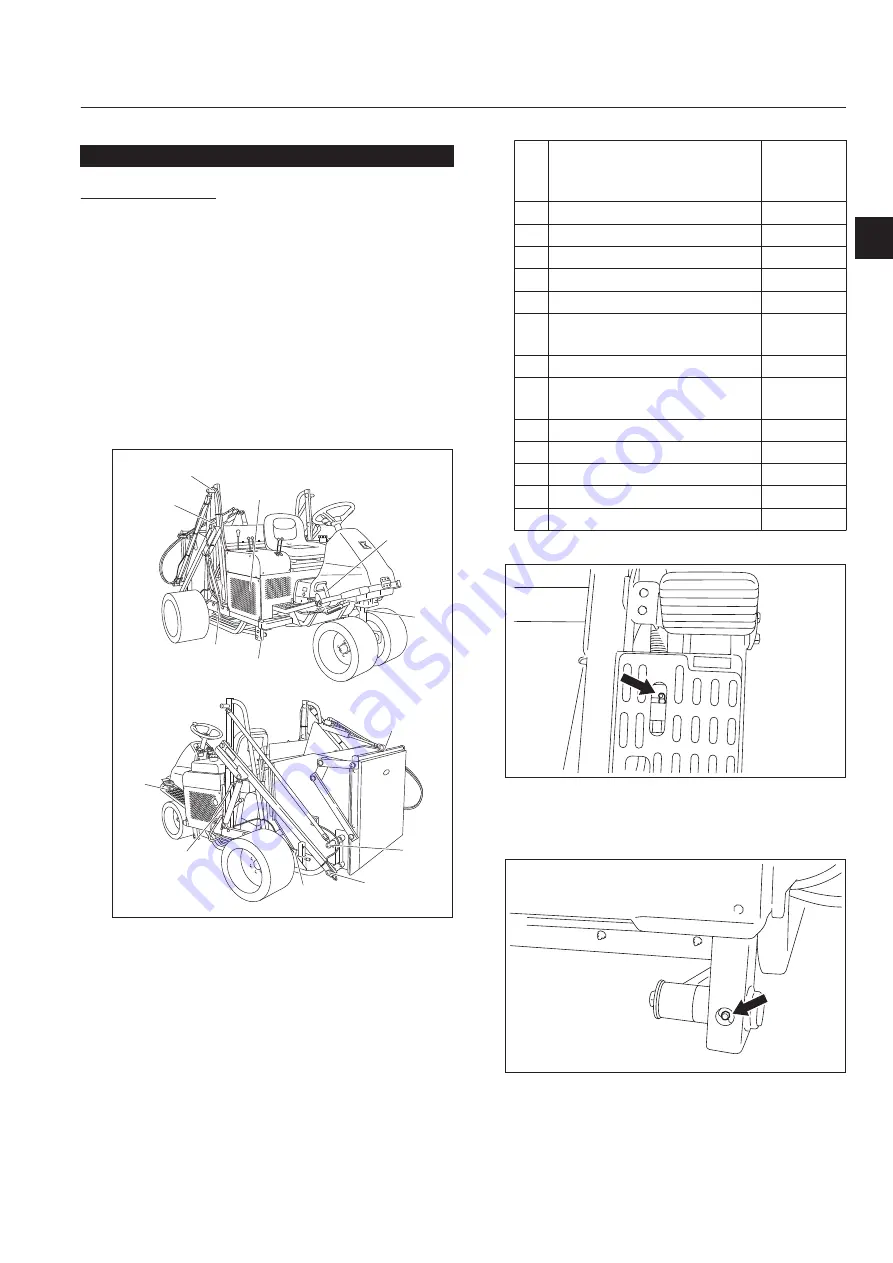

Greasing

About Greasing

Since there may be adhesion or damage due

to lack of grease on moving parts, they must

be greased.

Add urea-based No. 2 grease in accordance

with the Maintenance Schedule.

Other locations where the specified grease or

lubricant is used are indicated in "Greasing

Points".

Add grease using the specified grease or

lubricant.

Greasing Points

6

4

5

1

3

2

9

10

11

7

8

13

12

8bq62b-078

Greasing Points_001

Location

No. of

Greasing

Points

1

Traveling pedal fulcrum

1

2

Brush frame fulcrum

2

3

Flange bearing

1

4

Upper connecting pipe

2

5

Upper adjusting pipe

2

6

Belt tension lever fulcrum (lower pulley

for pump)

1

7

Brake pedal fulcrum

1

8

Pump neutral lever fulcrum (upper

piston pump)

1

9

Bucket lid cylinder

1

10

Lower adjusting pipe

2

11

Lower connecting pipe

2

12

Rear roller

2

13

Front wheel arm

1

Traveling pedal fulcrum

8bq62b-079

Greasing Points_002

Brush frame fulcrum

There is one point each on the left and

right.

8bq62b-080

Greasing Points_003

1.

2.

Maintenance standards and maintenance

FS900

Maintenance standards and maintenance

Page 3-13

Greasing

Summary of Contents for FS900

Page 1: ...Riding Sweeper Service Manual Serial No FS900 10001 Ver 1 0...

Page 4: ...FS900 Contents...

Page 10: ...FS900 Safety Page 1 6 Safety Signs and Instruction Signs...

Page 11: ...Waste Disposal Page 2 2 About the Waste disposal Page 2 2 Disposal FS900 Disposal Page 2 1...

Page 28: ...FS900 Maintenance standards and maintenance Page 3 16 Greasing...

Page 74: ...FS900 Hydraulic system Page 4 46 Inspection and repair of each section...

Page 98: ...FS900 Electrical system Page 5 24 General inspection and repair...

Page 118: ...FS900 Main body Page 6 20 Inspection and repair of each section...