page 73

page 73

page 73

page 73

page 73

275B SER

800-00152

S10A SWING MOTOR GEARBOX MAINTENANCE

S10A SWING MOTOR GEARBOX MAINTENANCE

S10A SWING MOTOR GEARBOX MAINTENANCE

S10A SWING MOTOR GEARBOX MAINTENANCE

S10A SWING MOTOR GEARBOX MAINTENANCE

CONTINUED...

CONTINUED...

CONTINUED...

CONTINUED...

CONTINUED...

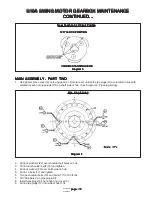

10. Roll test the unit in both clockwise and counterclockwise directions. Perform the same number of turns in

each direction as the ratio of the unit. The ratio is the same as the last two digits in the model number

found on the ID tag of the unit. For example, if the model number is S10AC4470, then it should be rolled

70 times in both directions.

11. Leak test the unit at a pressure of 8 P.S.I. for 2-3 minutes.

12. At this point, the main assembly is complete.

FILLING WITH OIL AND OIL CHANGE

FILLING WITH OIL AND OIL CHANGE

FILLING WITH OIL AND OIL CHANGE

FILLING WITH OIL AND OIL CHANGE

FILLING WITH OIL AND OIL CHANGE

INTERVALS

INTERVALS

INTERVALS

INTERVALS

INTERVALS

For normal applications, use EP90 gear fluid.

Fill until oil is as high as top of cluster bearings - see

illustration at right.

Check oil level daily.

Initial oil change should be done after 50 hours of

operating time. Change every 400 hours after that.

Minimum

Minimum

Minimum

Minimum

Minimum

1.02 inches

1.02 inches

1.02 inches

1.02 inches

1.02 inches

Maximum

Maximum

Maximum

Maximum

Maximum

.65 inches

.65 inches

.65 inches

.65 inches

.65 inches