page 60

page 60

page 60

page 60

page 60

275B SER

800-00152

MFE19 SWING MOTOR MAINTENANCE CONTINUED...

MFE19 SWING MOTOR MAINTENANCE CONTINUED...

MFE19 SWING MOTOR MAINTENANCE CONTINUED...

MFE19 SWING MOTOR MAINTENANCE CONTINUED...

MFE19 SWING MOTOR MAINTENANCE CONTINUED...

1

11

11

SCREWS

SCREWS

SCREWS

SCREWS

SCREWS

4

44

44

2

22

22

VALVE BLOCK

VALVE BLOCK

VALVE BLOCK

VALVE BLOCK

VALVE BLOCK

1

11

11

3

33

33

HOUSING

HOUSING

HOUSING

HOUSING

HOUSING

1

11

11

4

44

44

GASKET

GASKET

GASKET

GASKET

GASKET

1

11

11

5

55

55

BEARING & RACE

BEARING & RACE

BEARING & RACE

BEARING & RACE

BEARING & RACE

1

11

11

6

66

66

WAFER PLATE

WAFER PLATE

WAFER PLATE

WAFER PLATE

WAFER PLATE

1

11

11

7

77

77

PIN

PIN

PIN

PIN

PIN

1

11

11

8

88

88

SPACER

SPACER

SPACER

SPACER

SPACER

1

11

11

9

99

99

CYLINDER BLOCK

CYLINDER BLOCK

CYLINDER BLOCK

CYLINDER BLOCK

CYLINDER BLOCK

1

11

11

10

10

10

10

10 PISTON/SHOE ASSY

PISTON/SHOE ASSY

PISTON/SHOE ASSY

PISTON/SHOE ASSY

PISTON/SHOE ASSY 9

99

99

11

11

11

11

11 SHOE PLATE

SHOE PLATE

SHOE PLATE

SHOE PLATE

SHOE PLATE

1

11

11

12

12

12

12

12 SPHERICAL WASHER

SPHERICAL WASHER

SPHERICAL WASHER

SPHERICAL WASHER

SPHERICAL WASHER 1

11

11

13

13

13

13

13 PINS

PINS

PINS

PINS

PINS

3

33

33

14

14

14

14

14 PIN RETAINER

PIN RETAINER

PIN RETAINER

PIN RETAINER

PIN RETAINER

1

11

11

15

15

15

15

15 RETAINING RING

RETAINING RING

RETAINING RING

RETAINING RING

RETAINING RING

1

11

11

16

16

16

16

16 WASHER

WASHER

WASHER

WASHER

WASHER

1

11

11

17

17

17

17

17 SPRING

SPRING

SPRING

SPRING

SPRING

1

11

11

18

18

18

18

18 PIN WASHER

PIN WASHER

PIN WASHER

PIN WASHER

PIN WASHER

1

11

11

19

19

19

19

19 ALIGNMENT PIN

ALIGNMENT PIN

ALIGNMENT PIN

ALIGNMENT PIN

ALIGNMENT PIN

2

22

22

20

20

20

20

20 SWASH PLATE

SWASH PLATE

SWASH PLATE

SWASH PLATE

SWASH PLATE

1

11

11

21

21

21

21

21 SHAFT

SHAFT

SHAFT

SHAFT

SHAFT

1

11

11

22

22

22

22

22 BEARING & RACE

BEARING & RACE

BEARING & RACE

BEARING & RACE

BEARING & RACE

1

11

11

23

23

23

23

23 RETAINING RING

RETAINING RING

RETAINING RING

RETAINING RING

RETAINING RING

1

11

11

24

24

24

24

24 SHAFT SEAL (FRONT)

SHAFT SEAL (FRONT)

SHAFT SEAL (FRONT)

SHAFT SEAL (FRONT)

SHAFT SEAL (FRONT) 1

11

11

25

25

25

25

25 SHAFT SEAL (REAR)

SHAFT SEAL (REAR)

SHAFT SEAL (REAR)

SHAFT SEAL (REAR)

SHAFT SEAL (REAR) 1

11

11

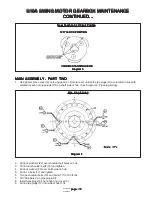

ITEM DESCRIPTION

ITEM DESCRIPTION

ITEM DESCRIPTION

ITEM DESCRIPTION

ITEM DESCRIPTION

QTY

QTY

QTY

QTY

QTY

Figure 8

Figure 8

Figure 8

Figure 8

Figure 8

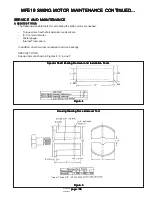

3. Clean the outside of the unit thoroughly to prevent entry of dirt into the system.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

Absolute cleanliness is essential when working on a hydraulic

Absolute cleanliness is essential when working on a hydraulic

Absolute cleanliness is essential when working on a hydraulic

Absolute cleanliness is essential when working on a hydraulic

Absolute cleanliness is essential when working on a hydraulic

system. Always work in a clean area. The presence of dirt and

system. Always work in a clean area. The presence of dirt and

system. Always work in a clean area. The presence of dirt and

system. Always work in a clean area. The presence of dirt and

system. Always work in a clean area. The presence of dirt and

foreign materials in the system can result in serious damage or

foreign materials in the system can result in serious damage or

foreign materials in the system can result in serious damage or

foreign materials in the system can result in serious damage or

foreign materials in the system can result in serious damage or

inadequate operation.

inadequate operation.

inadequate operation.

inadequate operation.

inadequate operation.

4. Periodic maintenance of the motor will generally not require disassembly to the extent described below. In general,

disassembly is accomplished in the item number sequence shown in Figure 8 on the next page. Special

procedures are included in the following steps under section B.

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: Discard and replace all o-rings, gaskets, and shaft seals removed during disassembly.

B.

B.

B.

B.

B. DISASSEMBLY OF PISTON MOTOR ROTATING GROUP AND VALVE BLOCK

DISASSEMBLY OF PISTON MOTOR ROTATING GROUP AND VALVE BLOCK

DISASSEMBLY OF PISTON MOTOR ROTATING GROUP AND VALVE BLOCK

DISASSEMBLY OF PISTON MOTOR ROTATING GROUP AND VALVE BLOCK

DISASSEMBLY OF PISTON MOTOR ROTATING GROUP AND VALVE BLOCK

NOTE:

NOTE:

NOTE:

NOTE:

NOTE: Refer to Figure 8 on next page throughout this procedure.

1. Remove four screws (1) from valve block (2). Separate valve block (2) and housing (3).

2. Remove gasket (4) then slide tapered roller bearing (5) from the end of shaft (21).

3. Remove wafer plate (6) from valve block (2) then remove pin (7) from valve block.

4. Slide bearing spacer (8) off shaft (21).

21

21

21

21

21

25

25

25

25

25

2

22

22

1

11

11

2

22

22

5

55

55

4

44

44

7

77

77

6

66

66

8

88

88

15

15

15

15

15

16

16

16

16

16

17

17

17

17

17

18

18

18

18

18

13

13

13

13

13

9

99

99

12

12

12

12

12

14

14

14

14

14

10

10

10

10

10

11

11

11

11

11

20

20

20

20

20

21

21

21

21

21

22

22

22

22

22

19

19

19

19

19

3

33

33

24

24

24

24

24

23

23

23

23

23

NOTE: -30 design

NOTE: -30 design

NOTE: -30 design

NOTE: -30 design

NOTE: -30 design

units have a drain

units have a drain

units have a drain

units have a drain

units have a drain

opening on top and at

opening on top and at

opening on top and at

opening on top and at

opening on top and at

bottom of valve block.

bottom of valve block.

bottom of valve block.

bottom of valve block.

bottom of valve block.

-20 and -21 designs

-20 and -21 designs

-20 and -21 designs

-20 and -21 designs

-20 and -21 designs

have one drain

have one drain

have one drain

have one drain

have one drain

opening. Also,

opening. Also,

opening. Also,

opening. Also,

opening. Also,

housing and gasket

housing and gasket

housing and gasket

housing and gasket

housing and gasket

are slightly different

are slightly different

are slightly different

are slightly different

are slightly different

from that shown.

from that shown.

from that shown.

from that shown.

from that shown.