black plug

torsion shaft

couple

bolt 3/8”

washer 3/8”

cable drum marked

with red paint

red plug

cable drum marked

with black paint

bolt 3/8”

washer 3/8”

roller bearing

slid

e

slid

e

roller bearing

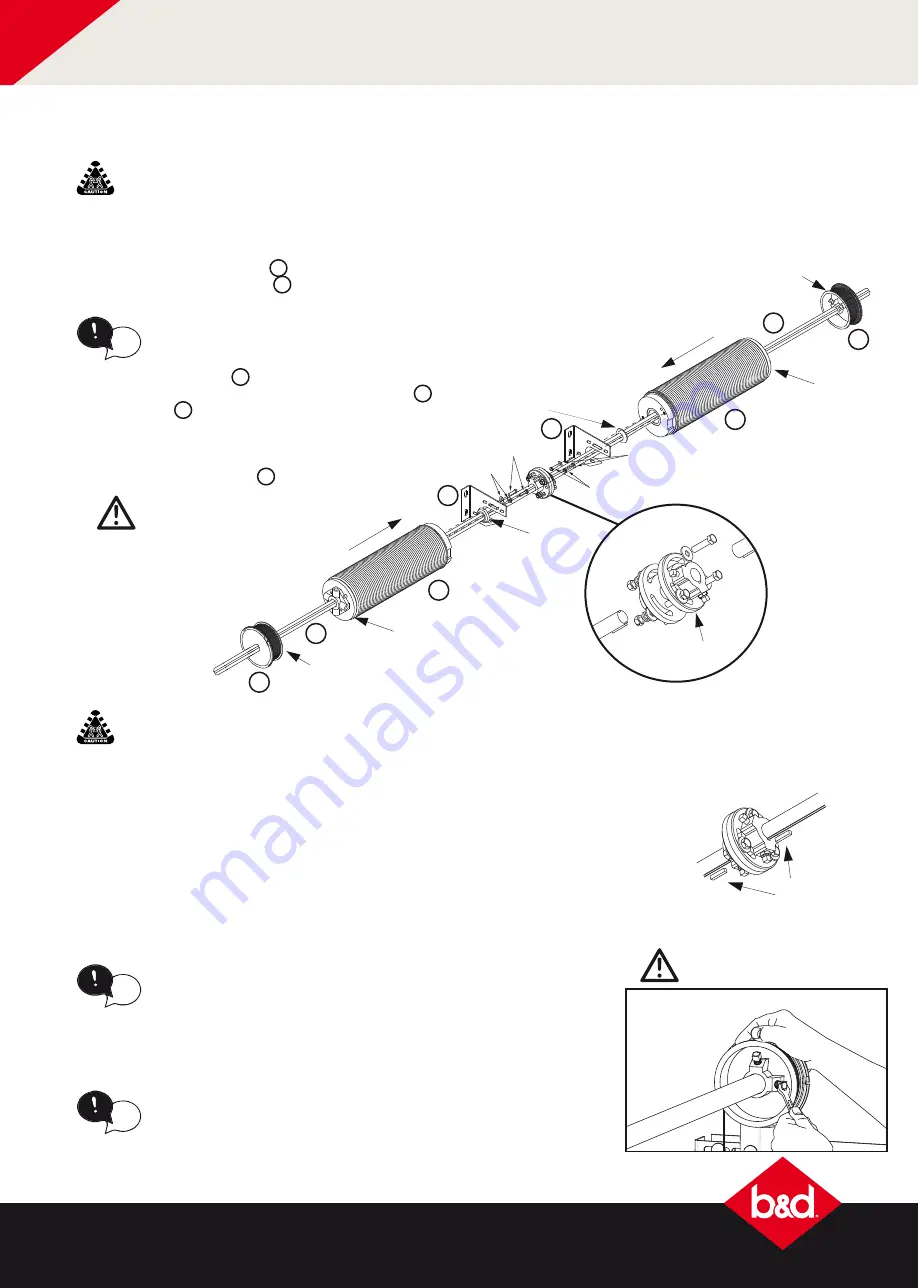

5.2 two piece shafts for large doors

The springs and drums for the counterbalance system are now colour coded to easily identify which

side of the centre bracket the spring is placed. Fig. 5.2.1.

a) Place the 2 x torsion bars

B

on the floor and slide the 2 x

HD spring anchor bracket

K

and roller bearings onto the

torsion bar, positioning them towards the middle.

b) Slide on the springs

I

, ensuring the roller bearing

is butted up against the spring anchor bracket

K

and spring

I

.

c) Connect each assembly together using 2 x 3/8”

washers and bolts.

d) Place the cable drums

J

on each end.

e) Mount the remaining 2 x spring

anchor brackets to the wall

above the horizontal track.

CAUTION:

DO NOT tighten

bolts in cable drums yet

TWO PERSON LIFT:

For large doors, this process may require two persons to lift into place and

a ladder or scissor lift to support while fixing into place.

TWO PERSON LIFT:

Next step may require two persons to lift into

place and a ladder or scissor lift to support while fixing into place.

insert key then fix into

place with grub screw

torsion

shaft key

torsion

shaft key

torsion

shaft key

Fig: 5.2.1

Fig: 5.2.2

a) Attach the lifting cable to the cable drum by slipping the cable into the slot

on the outside groove. (the ferrule will prevent the cable from coming out) .

b) Wind the cable by hand by turning the cable drum away from the door.

tip

Unwind the lifting cable from the

bottom panel.

CAUTION:

Be careful not to

over tighten the set-screws

Fig: 5.2.3

K

J

B

J

I

tip

The smaller end of the roller

bearing is to face the spring.

f) Lift and thread the right hand side of the assembly through the mounted spring

anchor bracket and fix the loose spring anchor bracket securely to the wall.

g) Assemble the torsion shaft couple, without tightening the bolts and slide onto

the end of the torsion bar, ready to connect to the other torsion bar.

h) Repeat step f) for the left hand side assembly.

i) Position the torsion shaft couple in the middle as shown in Fig 5.2.1, the axles

should be flush with each couple allowing free rotation to occur.

j) Cut torsion shaft key in half and insert into torsion bar at the torsion shaft

couple, and fix into place by tightening the grub screws on the shaft couple

Fig 5.2.2.

K

I

B

c) Once the cable is taut, slide the cable drum against the side bearing bracket

and tighten the screws to the torsion bar. Fig 5.2.3.

d) Proceed to section 3.8 to tension the springs.

tip

There must be no more than ONE turn of cable around the cable

drum. Too much cable will affect the spring tension.

20

The Designer Series

&

P7 Industrial

™

installation instructions