32

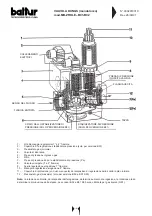

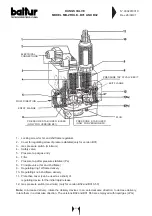

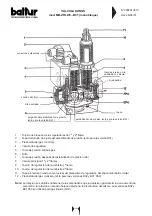

DUNGS VALVE

MODEL MB-ZRDLE...B01 AND B02

The monobloc DUNGS Model MB-ZRDLE is made up of:

a) Minimum gas pressure switch (3) and maximum gas pressure (12)

b) Gas filter (6)

c) Pressure regulator (stabilizer) (2) (only for version B01)

d) Safety valve (incorporated in the pressure regulator) which opens and closes rapidly (4)

e) Principle valve with two positions (1st flame and 2nd flame) which opens slowly with an adjustable initial rapid

release and rapid closing (8).

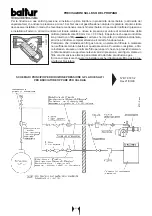

Before proceeding with regulation, read the following:

1) It is possible to reach the gas filter (6) in order to clean it, by removing one of the two side closing plates.

2) The pressure stabilizer can be regulated from 40 to 200 mm.W.C. by manoeuvring its regulating screw. It can be

reached by sliding the cover (2) to one side. The and viceversa is about 60 turns. Do not force against the end-of-

the-run position. Before starting up the burner, give the screw at least 15 turns towards the + sign. Around the

screw are arrows with symbols which indicate the sense of rotation to increase the pressure (in a clockwise

direction) and the sense of rotation to decrease pressure (in an anti-clockwise direction).

The stabilizer hermetically closes from “upstream” to “downstream” when there is no gas flow. Different springs to

obtain different pressure values form those described above are not foreseen.

To regulate the pressure stabilizer, connect a water manometer to the rubber tube holder installed on the valve, to

tap Pa (7), in correspondence with the stabilizer exit.

3) It is not necessary to regulate the rapid opening and closing safety valve (4).

4) Principle valve (8).

Regulating the initial rapid release effects the 1st and 2nd opening positions of the valve.

Regulation of the rapid release and of the hydraulic brake modify the 1st and 2nd positions of the valve in proportion

to the output regulated. To carry out regulation, unscrew the protection cover (11) and use the back part of it as a tool

to turn the pin.

Rotation in a clockwise direction

= minor rapid release

Rotation in an anti-clockwise direction = greater rapid release

REGULATING THE FIRST POSITION (1ST FLAME)

Loosen the screw with the protruding cylindrical head (1)

Give the knob (10), which regulates the output for the 2nd flame, at least one turn in the direction of the arrow which

indicates the + sign (anti-clockwise direction).

ATTENTION: If this knob which regulates the 2nd flame is not given at least one turn towards the + sign, the valve will

not open in the 1st position.

Rotate the regulating ring (9) of the 1st flame in the direction indicated by the arrow towards the + sign (anti-clockwise

direction). As an indication, this should be a little more than two turns from the end-of-the-run position.

Then, when the 1st flame only is alight, rotate adequately ring (9) in order to obtain the gas delivery desired.

The complete run of the output regulator, from the - position to the + position, and viceversa, is about three and a half

turns. Rotation of the regulator in a clockwise direction, determines a reduction in delivery; rotation in an anticlockwise

direction increase delivery.

REGULATING THE SECOND POSITION (2ST FLAME)

Loosen the screw with the protruding cylindrical head (1)

Rotate the knob (10) in the direction indicated by the arrow for the + sign (anti-clockwise direction) as considered

necessary in order to obtain the gas delivery required for the 2nd flame.

The complete run of the regulator from the - position to the + position, and viceversa, is about FIVE turns. Rotate in a

clockwise direction to determine a reduction in delivery and in an anti-clockwise direction to increase it.

After regulating the gas delivery for the 1st and 2nd flame,remember to tighten home the screw (1) to avoid the

regulatormoving out of the position at which it has been set.

N° 0002910310

Rev. 26/09/97

1st POSITION

2nd POSITION

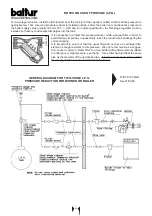

DETAILS OF TERMINAL BOARD

FOR VALVE MB-ZRDLE...

VALVE

INLET MAX PRESSURE

ADJUSTTABLE OUTLET PRESSURE

TYPE OF GAS

MODEL

(PE) mbar

FROM THE STABILIZER (PA) mbar

MB ...B01 S 20

200

from 4 to 20

Gas maturale

MB ... B01 S 50

360

from 4 to 50

L.P.G

MB ... B02

360

L.P.G.

Summary of Contents for SPARKGAS 3,6

Page 14: ...14...

Page 15: ...15...

Page 16: ...16...

Page 17: ...17...

Page 27: ...27...

Page 28: ...28...

Page 29: ...29...

Page 30: ...30...

Page 40: ...40...

Page 41: ...41...

Page 42: ...42...

Page 43: ...43...

Page 53: ...53...

Page 54: ...54...

Page 55: ...55...

Page 56: ...56...

Page 66: ...66...

Page 67: ...67...

Page 68: ...68...

Page 69: ...69...