47 / 119

0006081062_200709

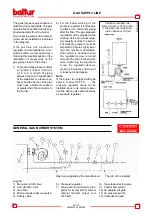

IGNITION AND GAS

REGULATION (METHANE)

1)

Make sure that the combus-

tion head penetrates into

the combustion chamber by

the quantity required by the

manufacturer.

Check that the

device that turning off the air

on the combustion head is in the

proper position for the required

fuel supply (the air passage

between disk and head must

be sensibly reduced in case of

low fuel supply. In the contrary

case, if the fuel supply is quite

high, the air passage between

disk and head must be opened).

See chapter “Combustion head

regulation”.

2) If not already done when con

-

necting the burner to the gas

pipes, taking the necessary

measures and opening doors

and windows, it is necessary

to bleed the air contained in

the pipes. Open the union on

the pipes close to the burner,

and slightly open the gas stop

cock(s). Wait until you smell the

typical gas smell, and then close

the cock. Wait for the necessary

time, according to the specific

conditions, until the gas present

in the room is dispersed outside

and then restore the connection

of the burner to the gas piping.

3)

Check that there is water in

the boiler and that the plant

dampers are open.

4)

Make sure that the combus-

tion product discharge can

occur freely (boiler and chim-

ney dampers open).

5) Check that the electrical line

voltage corresponds to that re-

quired for the burner, and that

the electrical connections (mo-

tor and main line) are preset

for the available voltage value.

Check that all electrical con

-

nections implemented on the

spot are properly executed as

per our wiring diagram.

6) Apply a pressure gauge with

suitable scale to the gas pres-

sure take-off to measure the

regulation value (if the expected

pressure rate allows it, it is pref

-

erable to use a water column

instrument,

do not

use hand

instruments for low pressures).

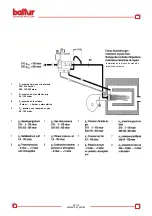

7) Regulate the air for the ignition

flame, for minimum flame and

high flame, following the instruc

-

tions for regulating air damper

control electrical motor shown in

the following pages

.

In practice,

set the low flame and high flame

air regulation cams to the suit-

able positions according to the

desired thermal power for low

and high flame.

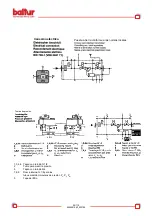

8) By acting on the special

screw for adjusting the gas

and air pressure ratio, on the

gas valve

mod. MB-VEF..,

DMV-VEF.., set the desired

value (see the specific instruc

-

tions for the gas valve MB-VEF..,

DMV-VEF.. in the following

pages).

9) With the burner panel switch set

to “0” and main circuit breaker

on, manually turn the contactor

off and check that the motor runs

in the correct direction. If nec-

essary, invert the place of two

cables of the line supplying the

three-phase motor to reverse

the direction of rotation

.

10)

I n s t r u c t i o n s f o r m a n u a l

mode working of the burner

Combustion control can be

carried out over the whole mo

-

dulation range while manually

controlling the MPA 22 equip-

ment. For this use modulation

connector (B) in the diagram,

which is provided with the burner

as standard. After disconnecting

the 4-pole plug (A) which takes

the signals from the thermostat

or the RWF 40 adjustor, insert

the connector in position (B).

Use the +/- buttons to increase

or reduce the gas and air supply.

After this control, put the 4-pole

plug (A) back in so as to reset

automatic mode modulation.

Note

:

Pre-ventilation is carried out

with open air and thus, dur

-

ing the same, the regulation

servomotor is enabled, and it

runs a complete opening stroke

up to the “maximum” set. Only

when the regulation servomotor

returns to the “ignition” position,

the control box continues its

ignition program by enabling

the transformer and the ignition

gas valves.

During the pre-ventilation step,

make sure that the air pressure

control switch changes position

(from off position without pressure

detection it must switch to the off

position with air pressure detec

-

tion). If the air pressure switch

does not detect the sufficient pres

-

sure (it does not switch position),

the ignition transformer and the

flame gas valves are not enabled,

and thus the control box “locks”.

To “unlock”, press the “unlock” push

button(8). At the first stage there

may occur further “locks” due to:

a) The gas pipes have not been

sufficiently air-bled, and thus the

gas quantity is not sufficient to

allow a stable flame.

b) The “lock” with presence of flame

may be caused by instability of

the same in the ionisation zone

for an incorrect air/gas ratio.

Remedy is by varying the quan

-

tity of supplied air and/or gas so

as to find the correct ratio. The

same problem may be caused

by a wrong air/gas distribution

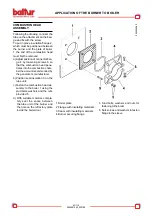

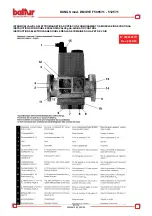

Summary of Contents for BGN 200 LX

Page 35: ...98 119 0006081062_200709...

Page 36: ...99 119 0006081062_200709...

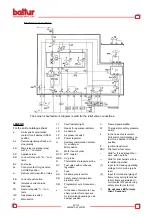

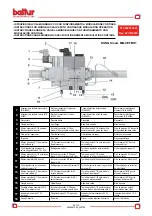

Page 44: ...107 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Page 45: ...108 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Page 46: ...109 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Page 47: ...110 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Page 48: ...111 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Page 49: ...112 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Page 50: ...113 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Page 51: ...114 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Page 52: ...115 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Page 53: ...116 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Page 54: ...117 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Page 55: ...118 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Page 56: ...119 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...