MN715J

Troubleshooting 5-9

Electrical Noise Considerations

All electronic devices are vulnerable to significant electronic interference

signals (commonly called “Electrical Noise”). At the lowest level, noise can

cause intermittent operating errors or faults. From a circuit standpoint, 5 or 10

millivolts of noise may cause detrimental operation. For example, analog

speed inputs are often scaled at 5 to 10VDC maximum with a typical

resolution of one part in 1,000. Thus, noise of only 5 mV represents a

substantial error.

At the extreme level, significant noise can cause damage to the drive.

Therefore, it is advisable to prevent noise generation and to follow wiring

practices that prevent noise generated by other devices from reaching

sensitive circuits. In a control, such circuits include inputs for speed, control

logic, and speed and position feedback, plus outputs to some indicators and

computers.

Relay and Contactor Coils

Among the most common sources of noise are the ever-present coils of

contactors and relays. When these highly inductive coil circuits are opened,

transient conditions often generate spikes of several hundred volts in the

control circuit. These spikes can induce several volts of noise in an adjacent

wire that runs parallel to a control-circuit wire.

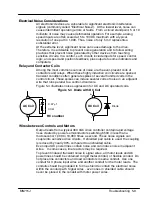

Figure 5-4 illustrates noise suppression for AC and DC operated coils.

Figure 5-4 Diode with DC Coil

AC Coil

DC Coil

RC snubber

0.47

m

f

Diode

-

+

33

W

Wires between Controls and Motors

Output leads from a typical 460 VAC drive controller contain rapid voltage

rises created by power semiconductors switching 650V in less than a

microsecond, 1,000 to 10,000 times a second. These noise signals can

couple into sensitive drive circuits. If shielded pair cable is used, the coupling

is reduced by nearly 90% compared to unshielded cable.

Even input AC power lines contain noise and can induce noise in adjacent

wires. In some cases, line reactors may be required.

To prevent induced transient noise in signal wires, all motor leads and AC

power lines should be contained in rigid metal conduit, or flexible conduit. Do

not place line conductors and load conductors in same conduit. Use one

conduit for 3 phase input wires and another conduit for the motor leads. The

conduits should be grounded to form a shield to contain the electrical noise

within the conduit path. Signal wires - even ones in shielded cable should

never be placed in the conduit with motor power wires.

Summary of Contents for ID15J101-ER

Page 1: ...Series 15J Inverter Control 7 04 MN715J Installation and Operating Manual ...

Page 5: ...iv Table of Contents MN715J ...

Page 11: ...2 4 General Information MN715J ...

Page 59: ...4 22 Programming and Operation MN715J ...

Page 75: ...6 6 Specifications and Product Data MN715J ...

Page 79: ...A 4 Dynamic Brake Hardware MN715J ...

Page 86: ...Appendix C Remote Keypad Mounting Template MN715J Remote Keypad Mounting Template C 1 ...