PanaFlow Z1G/Z2G

Quick-Start Guide

1100 Technology Park Drive, Billerica, MA 01821, U.S.A.

Telephone: 978-437-1000 or 800-833-9438

Sensing House, Shannon Free Zone East, Shannon, County Clare, Ireland

Telephone: +353 61 470200

916-149, Rev. A

Jun 2018

Electrical Wiring and Programming Instructions (see other side for Installation Instructions)

4. Making the Electrical Connections

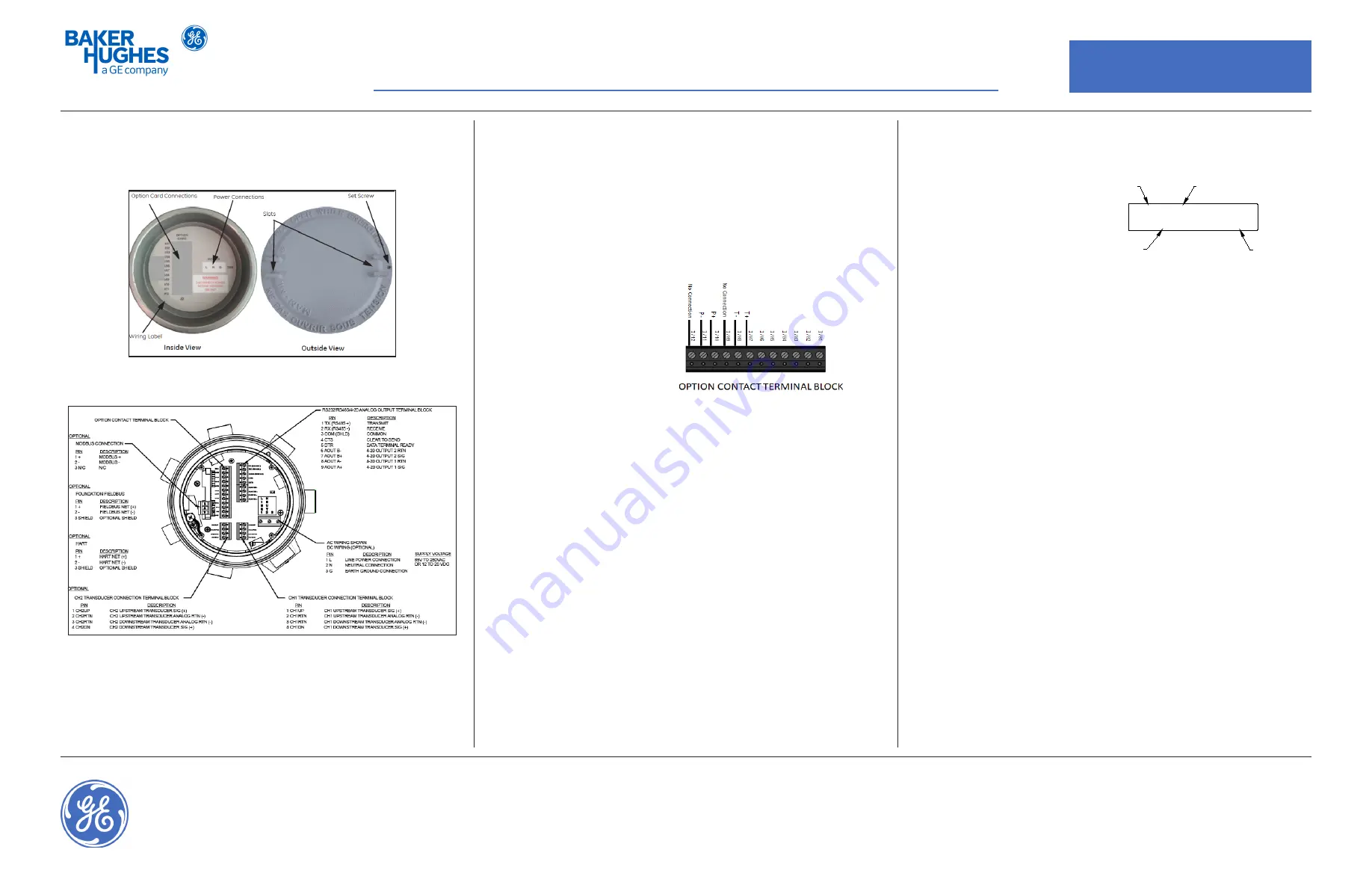

To prepare the PanaFlow Z1G/Z2G Process Gas Flowmeter for wiring, refer to

Figure 6 and Figure 7

, and complete the following steps:

Figure 6: Rear Cover with Connection Labels

Figure 7: Transmitter Electronics - Wiring Diagram (Removed Rear Cover

View)

5. Operation

The PanaFlow Z1G/Z2G Process Gas Flowmeter does not have an ON/OFF

switch, it will power up as soon as the connected power source is energized.

There are three methods for obtaining readings from the PanaFlow Z1G/Z2G

Process Gas Flowmeter

(Refer User Manual)

:

•

Built-in PanaFlow Z1G/Z2G Process Gas Flowmeter LCD display

•

PanaView software installed on a personal computer

•

External analog device to read the PanaFlow Z1G/Z2G Process Gas

Flowmeter analog output.

5.1

PanaFlow Z1G/Z2G Process Gas Flowmeter LCD Display

The PanaFlow Z1G/Z2G Process Gas Flowmeter display screen includes the

following information:

•

Channel Number

•

Flow Parameter

•

Units of Measure

•

Flow Rate Value

5.2

Programming the LCD Display

The Flowmeter is pre-programmed, to modify the program use the Keypad

Program. Complete the following steps to program the LCD display:

Refer User

Manual

.

1. Power up the PanaFlow Z1G/Z2G Process Gas Flowmeter and wait until

it has initialized.

To enter the Keypad Program, press the [

] key,

followed by the [

] key, and the [

] key again. Each successive key must

be entered within 10 seconds of the prior key.

2. In the Keypad Program window, scroll to PROG and press [

]. In the

PROG menu, scroll to GLOBL and press [

].

3. Scroll to I/O and press [

]. and scroll to LCD and press [

].

4. At the # of LCD Parameters screen, scroll to the desired number (from

OFF through 1-4 and KEY) and press [

]. The OFF setting switches the

measurement display Off. The KEY setting enables users to change the

measurement display with the arrow keys, without accessing the Keypad

Program. If you select KEY:

•

To view a parameter other than the one currently displayed, press the

[

] and [

] keys to scroll through the various available parameters.

5. Select the desired Measurement Parameter.

Wiring the Transducers (Remote

Mount only, Refer Section-3)

Refer User Manual 910-321 Sec 2.4.2

Wiring the Standard 4-20mA

Analog Outputs

Refer User Manual 910-321 Sec 2.4.3

Wiring the Standard RS485 Serial

Port

Refer User Manual 910-321 Sec 2.4.4

Wiring the Option Cards (For PT

Sensor only)

Refer User Manual 910-321 Sec 2.4.5

Wiring the Line Power

Refer User Manual 910-321 Sec 2.4.1

Ch1 MDOT

0.00

LB/SEC

Parameter

Channel #

Units

Flow Rate