37

37

Lubrication

Lubricate the bare metal locations on the lathe on a regular basis with light machine oil to

prevent rust and corrosion.

Motor Service

Keep the motor as clean as possible. Prevent any water, oil, or wood chips from entering inside

the motor housing. Be sure to clean the machine after every use.

The bearings inside the motor are shielded and lubricated for the life of the bearing and require

no routine maintenance.

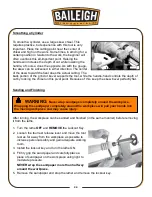

This motor is equipped with long life carbon brushes. However, brush life expectancy is affected

by motor loading. Heavy motor loading will result in reduced brush life. Check brushes after

every 40

– 50 hours of operation.

1.

Unplug or disconnect lathe from power source and lock out power.

2. One at a time, remove the brush cap and brush and spring assembly.

3.

Measure the brush length. When the brushes are worn down to 1⁄4'' (6mm), replace them.

Note: When checking brushes, be sure to return each brush in the same position

that it came from. When replacing old brushes, be sure to replace both brushes at the same

time.

4. Install the brush into the brush holder being sure that the brush moves freely.

5. Install the brush cover being careful not to pinch the brush spring.

A

A

Summary of Contents for WL-1218VS

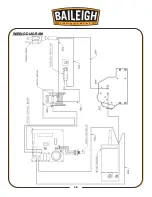

Page 41: ...38 38 WIRING DIAGRAM ...

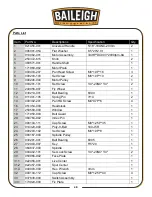

Page 42: ...39 39 LATHE PARTS DIAGRAM ...

Page 49: ...46 46 NOTES ...

Page 50: ...47 47 NOTES ...

Page 51: ...48 48 NOTES ...