32

32

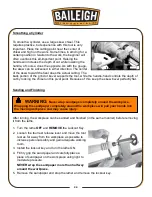

Tool Rest Position

Mount the tool rest in place about 1/8” away from the

work and 1/8” above the work centerline. This position

may be varied to suit the work and the operator. Place a

guide mark on the tool rest shank as an aid to quick and

accurate resetting.

Roughing a Cylinder

The large gouge is used in the first turning operation by

smoothing the sharp corners of the work. Run the lathe

at low speed and hold the gouge as shown at right.

The cut starts about 2 inches from the tailstock end and

continues from this point to the end of the tailstock.

Make the second pass beginning about 2” or 3” to the

left of the first cut. Advance again toward the tailstock,

and merge with the previous cut.

Toward the end of the live center, roll the gouge in the

opposite direction to carry the final cut off the live

center end of the work. The roughing cut should not be

carried out with one continuous movement, because

this would tear long slivers from the corners of the

work. Neither should the cut be started directly at the

end of the stock for the same reason. The cut can be

safely carried from the center of the stock toward and

off either end once the first roughing cuts have been

made. The position of the gouge involves two or three

important angles.

1. The tool may be advanced along the work either from right to left or from left to right. Left to

right (from headstock to tailstock) is preferred since this action throws chips clear of the

operator.

2. The gouge is rolled over slightly in the same direction it is advancing.

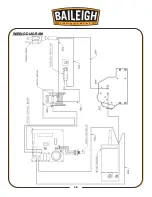

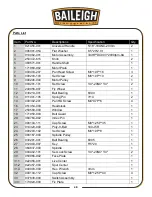

Summary of Contents for WL-1218VS

Page 41: ...38 38 WIRING DIAGRAM ...

Page 42: ...39 39 LATHE PARTS DIAGRAM ...

Page 49: ...46 46 NOTES ...

Page 50: ...47 47 NOTES ...

Page 51: ...48 48 NOTES ...