23

23

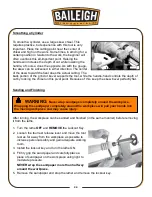

3. Place index pin (C) in one of the three

holes (D) and place faceplate wrench (E)

on faceplate shoulder flats and turn wrench

to loosen faceplate.

4. Once loose, the faceplate (F) can be

unscrewed.

Replacement Face Plate

1. To re-attach faceplate, screw it back on to the

spindle nose.

2. Tighten securely using the index pin and

faceplate wrench.

3. Tighten set screws securely.

Directions for mounting a workpiece to the

faceplate can be found later in this manual.

Index Pin

Indexing on a lathe is typically used for workpiece layout and other auxiliary operations that

require equal distances around the workpiece circumference, such as clock faces or inlays.

By inserting the indexing pin into one of the three outer indexes of the lathe spindle housing and

engaging one of the twelve inner indexes in the spindle, the workpiece can be positioned one of

36 equal points.

1. Turn off and unplug the lathe from the power

source.

2. To use the indexing feature, rotate the

flywheel (A) so spindle is in desired location.

3. Place the index pin (B) into one of the

indexing holes (C) in the headstock.

IMPORTANT: Do not start the lathe

with the indexing pin inserted into the spindle.

This will cause damage to the lathe.

C

D

E

F

A

C

B

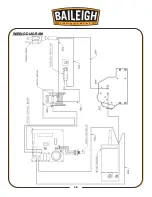

Summary of Contents for WL-1218VS

Page 41: ...38 38 WIRING DIAGRAM ...

Page 42: ...39 39 LATHE PARTS DIAGRAM ...

Page 49: ...46 46 NOTES ...

Page 50: ...47 47 NOTES ...

Page 51: ...48 48 NOTES ...