28

28

Snipe

Snipe refers to a depression at either end of the board caused by an uneven force on the

cutterhead when the work is entering or leaving the planer. Snipe may occur when the board is

not supported properly or when only one feed roller is in contact with the board at the beginning

or end of the cut.

•

If the snipe is deep, be more careful how the board is supported. Keep it parallel to and flat

on the table at all times. Use an extra support, such as a roller stand, at both the infeed and

outfeed ends of the planer.

•

Other methods to prevent snipe are reducing the depth of cut, and feeding additional boards

butted closely to leading and trailing ends of the workpiece.

•

If snipe cannot be avoided, cut the material longer than needed and trim the ends after

planing.

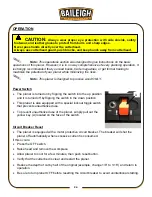

Planing Warped Wood

Note: If a significantly cupped board is fed into the planer, the feed rollers will press it flat

for the pass, but the wood will spring back into cupped form when it has cleared the rollers. For

best results, one side of the material should be run through a jointer to achieve a flat surface

prior to planing. However, if a board is only moderately cupped you may attempt to plane it.

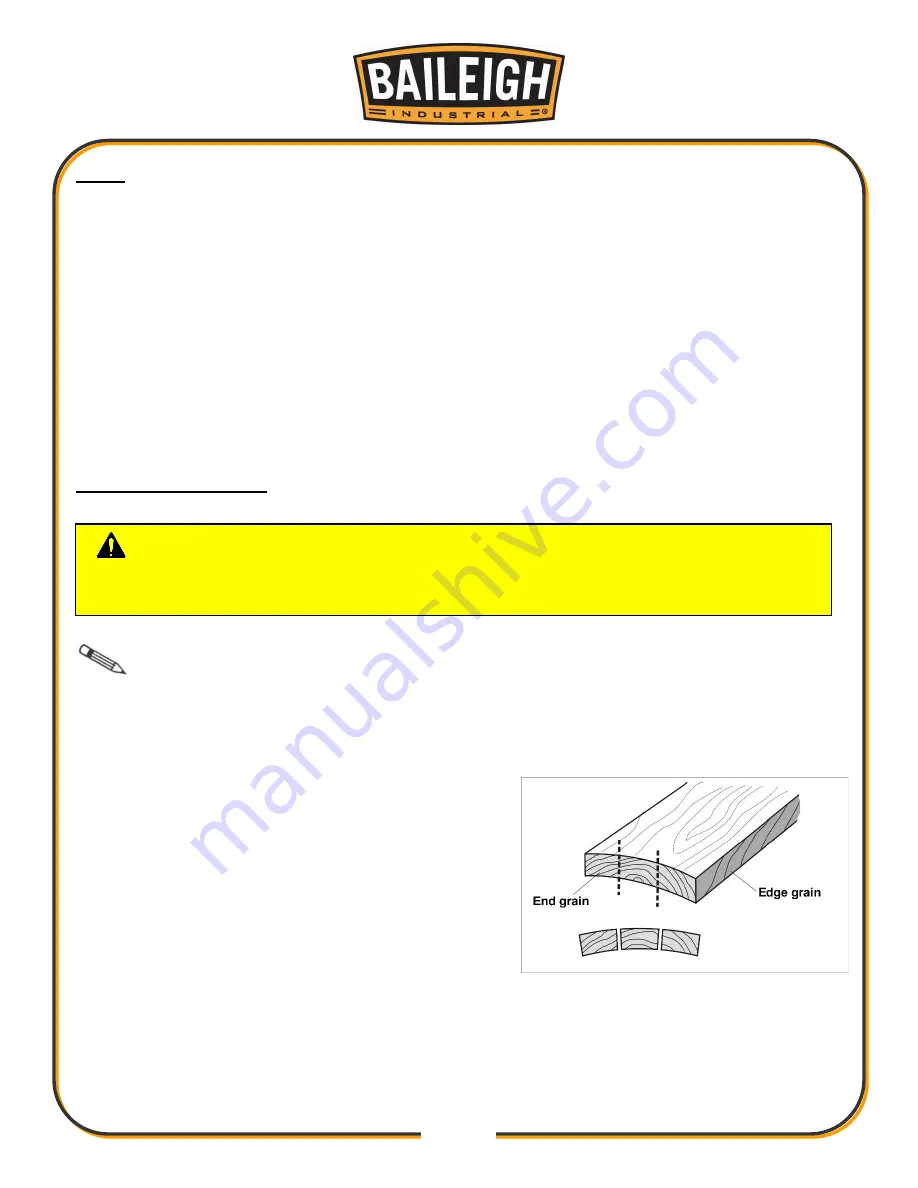

•

If the board is narrow enough, consider using a

table saw or band saw to rip the top of the warp

before planing the board. If this is not practical,

feed the board into the planer concave side down

and plane the top of the board until it presents a

flat surface.

•

Turn the board over and plane the bottom edges

until they are flush with the middle. After planing

the board, use a table saw or band saw to square

the board’s edges with the top and bottom

surfaces.

•

Cupping can often be diminished by ripping the board into narrower pieces on a table saw or

band saw.

CAUTION:

Do not attempt to plane a board which is warped along its

length. A warped board can jam itself against the cutterhead knives resulting in

kickback and/or damage to the planer.

Summary of Contents for IP-1306

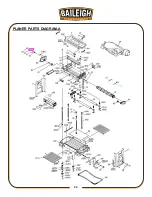

Page 38: ...35 35 PLANER PARTS DIAGRAM A...

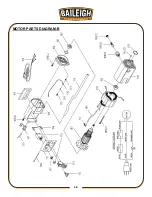

Page 43: ...40 40 MOTOR PARTS DIAGRAM B...

Page 47: ...44 44 NOTES...