33

33

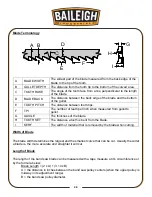

Adjusting Blade Tension

Blade tension is important to the proper operation of the saw. The

saw should be set in the

“High Tension” range (about 2,300 psi)

when you are finished with the blade tension setup.

To set the blade tension without the use of a blade tension gauge:

1. Install blade onto the pulleys and insert between the bearings on

the blade guides.

2. Loosen the two hex bolts.

3. Tension the blade slightly by turning the knob clockwise (cw), to

remove any sag of the blade between the bearing wheels.

4. Now turn the knob an additional 1-3/4 - 2 turns clockwise (cw).

This equals approximately 2,300 lbs. of blade tension. Use the

Dynametric Tension Band setting as a reference.

5. Once the white indicator line is centered in the blue section, re-

tighten the two hex bolts.

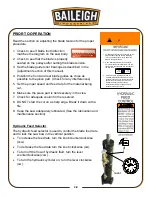

Adjusting Bow Weight

The extension spring which helps control the

downward movement of the saw bow was preset at

the factory. No additional adjustment to the spring

should be necessary.

NOTICE: Lifting and

Do not overtighten the blade. This

may cause the blade to stretch and warp.

Loosen

High

Tension

Low

Tension

approx.

2,300 lbs.

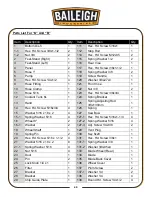

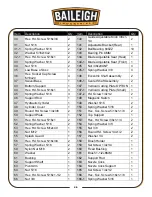

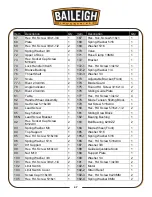

Summary of Contents for BS-712MS

Page 17: ...14 14 OVERALL DIMENSIONS...

Page 18: ...15 15 GETTING TO KNOW YOUR MACHINE A B C D E F G H I K J L...

Page 32: ...29 29...

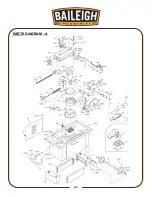

Page 46: ...43 43 PARTS DIAGRAM A...

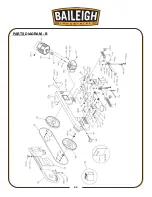

Page 47: ...44 44 PARTS DIAGRAM B...

Page 58: ...55 55 NOTES...

Page 59: ...56 56 NOTES...