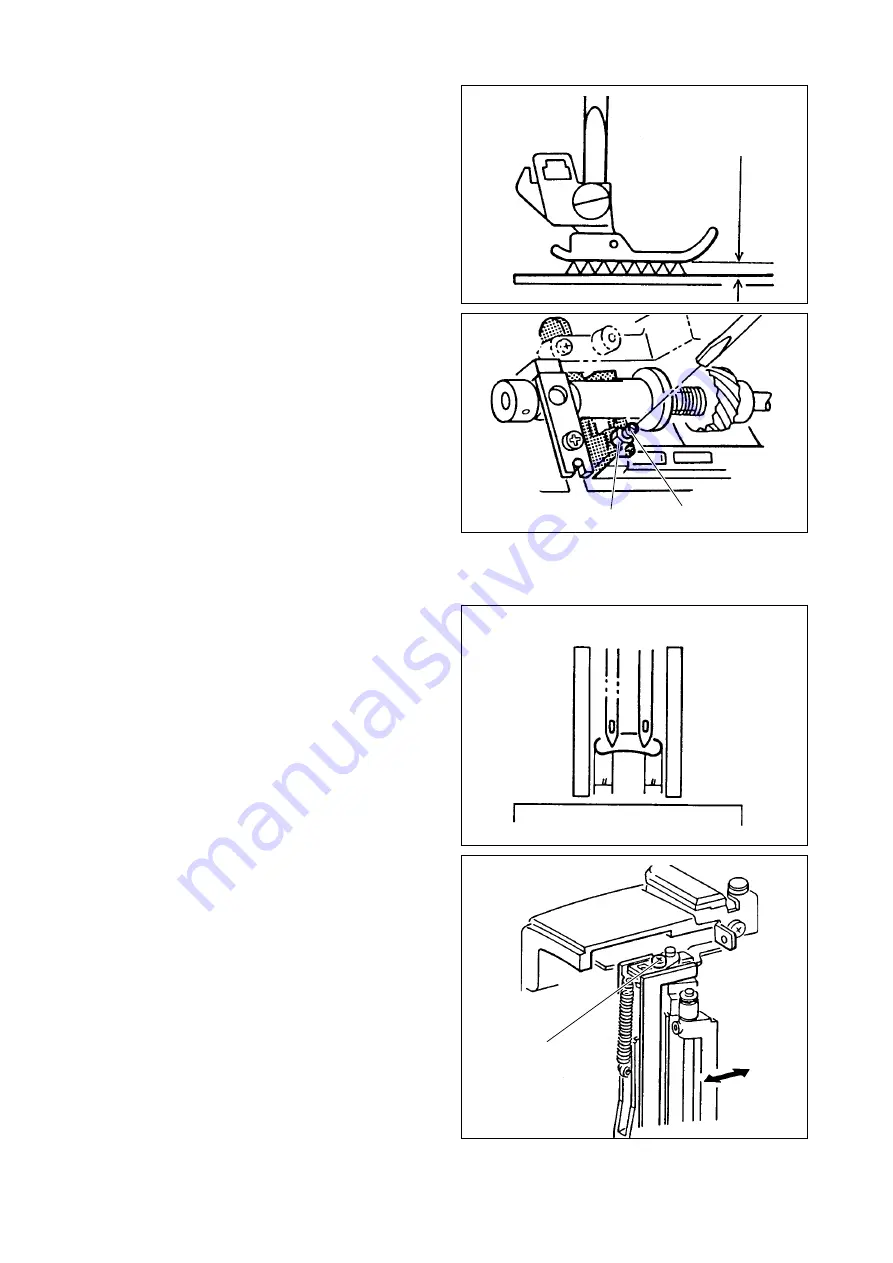

fig. 4-1

fig. 4-2

0.8

+0.05

mm

-0

a

b

fig. 5-1

fig. 5-2

a

- 8 -

4. HEIGHT OF THE FEED DOG

If the feed dog does not come up over the needle plate

enough, it will result in insufficient and/or uneven feed of

fabrics.

The feed dog should come up over the needle plate

0.8

+0.05

-0

mm. (fig. 4-1)

If it does not come up enough, adjust as follows:

1. Tilt the machine backward and remove the bed lid by

removing the screw and sliding it to the left. (See sec.

3-5)

2. Lower the presser foot lifter. Turn the handwheel until

the feed dog comes to its highest position.

3. Loosen the lock nut (a). Adjust the height of the feed

dog correctly by turning the inner screw (b). (fig. 4-2)

4. Hold the screw (b) and re-tighten the lock nut (a).

5. Re-check the height and motion of feed dog by turning

the handwheel.

5. NEEDLE PLATE AND NEEDLE

POSITON

When the zigzag width is set at maximum, the needle

should fall evenly into the both sides of needle plate hole (

the distance needle and edge of hole at each side). (fig.

5-1) If it is not so, adjust as follows:

1. Set the pattern number at “4” and stitch width to 5.

2. Remove the presser foot and the light cover.

3. Loosen the screw (a) located on the top of the needle

bar guide assembly. (fig. 5-2)

By slightly moving the needle bar left or right, adjust

the needle position so that the needle falls evenly into

the hole.

4. Tighten the screw (a) and re-check the position of

needle.