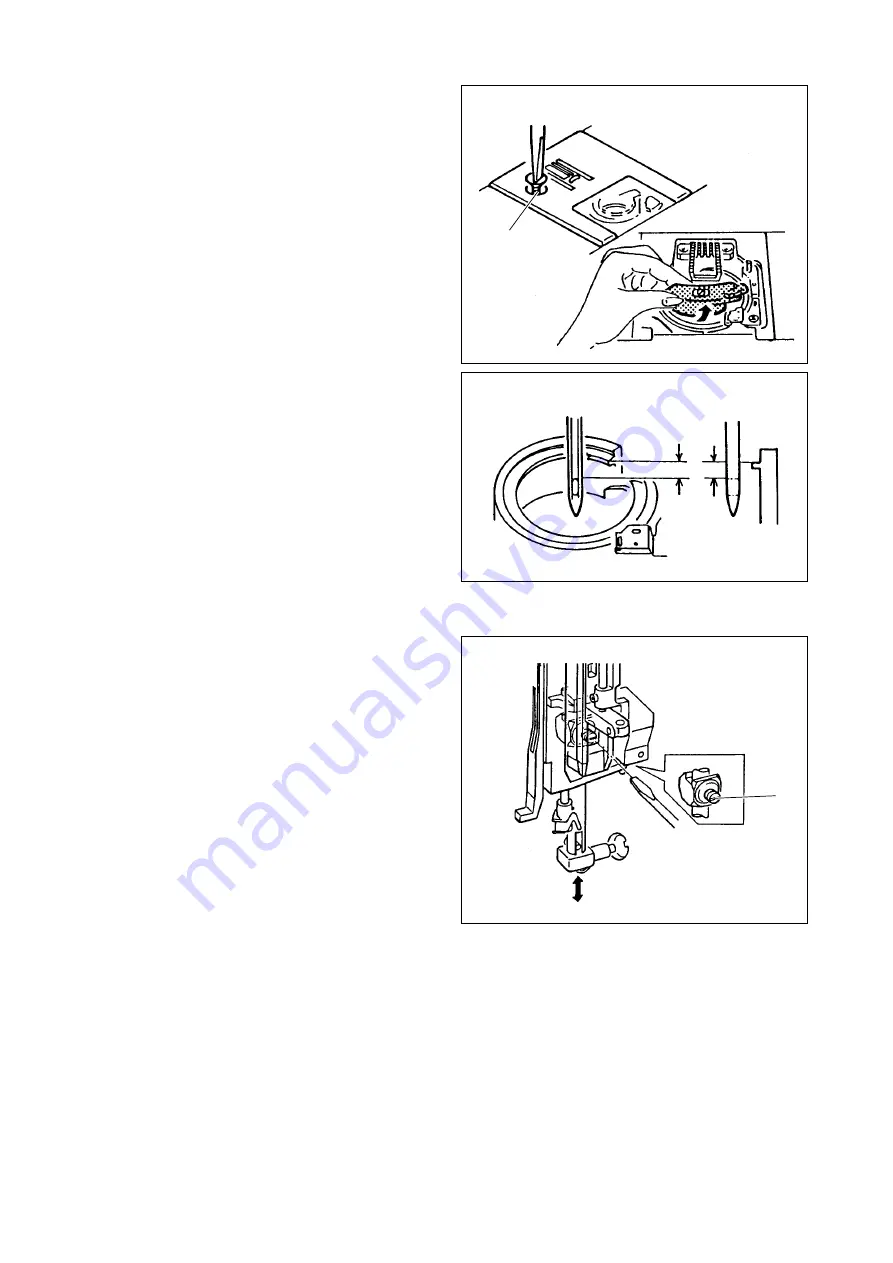

fig. 1-1

fig. 1-2

fig. 1-3

a

5.2

±

0.2 mm

b

- 5 -

1. HEIGHT OF NEEDLE BAR

Height of needle bar could be the cause for stitches to

skip. Check as the following procedures.

1. Set the pattern number at “2” which is straight stitch on

center needle position.

2. Raise the needle bar to its highest point by turning the

handwheel toward you. Remove the presser foot.

Remove the set screw (a) and needle plate. Lift up the

bobbin holder and remove it. (fig. 1-1)

3. Turn the handwheel toward you until the needle comes

to its lowest point.

Then, the spacing between the surface of hook race

and the top edge of needle eye must be 5.2

±

0.2 mm.

(fig. 1-2)

(= Turn the handwheel until the top edge of needle eye

is aligned with the surface of hook race, at this time the

needle bar should be rising 5.2

±

0.2 mm from its lowest

point.)

If this spacing is not correct, adjust as follows.

4. Remove the light cover.

5. Lower the needle to its lowest point by turning the

handwheel.

6. Loosen (not remove) the screw (b) on the needle bar

holder. (fig. 1-3)

Raise the needle bar until the needle eye is aligned

with the hook race. Then, lower the needle bar 5.2 mm

and re-tighten the screw (b).

CAUTION: DO NOT change the needle bar direction at

this adjustment. The long groove of needle must be

facing frontwards.