-61-

32.

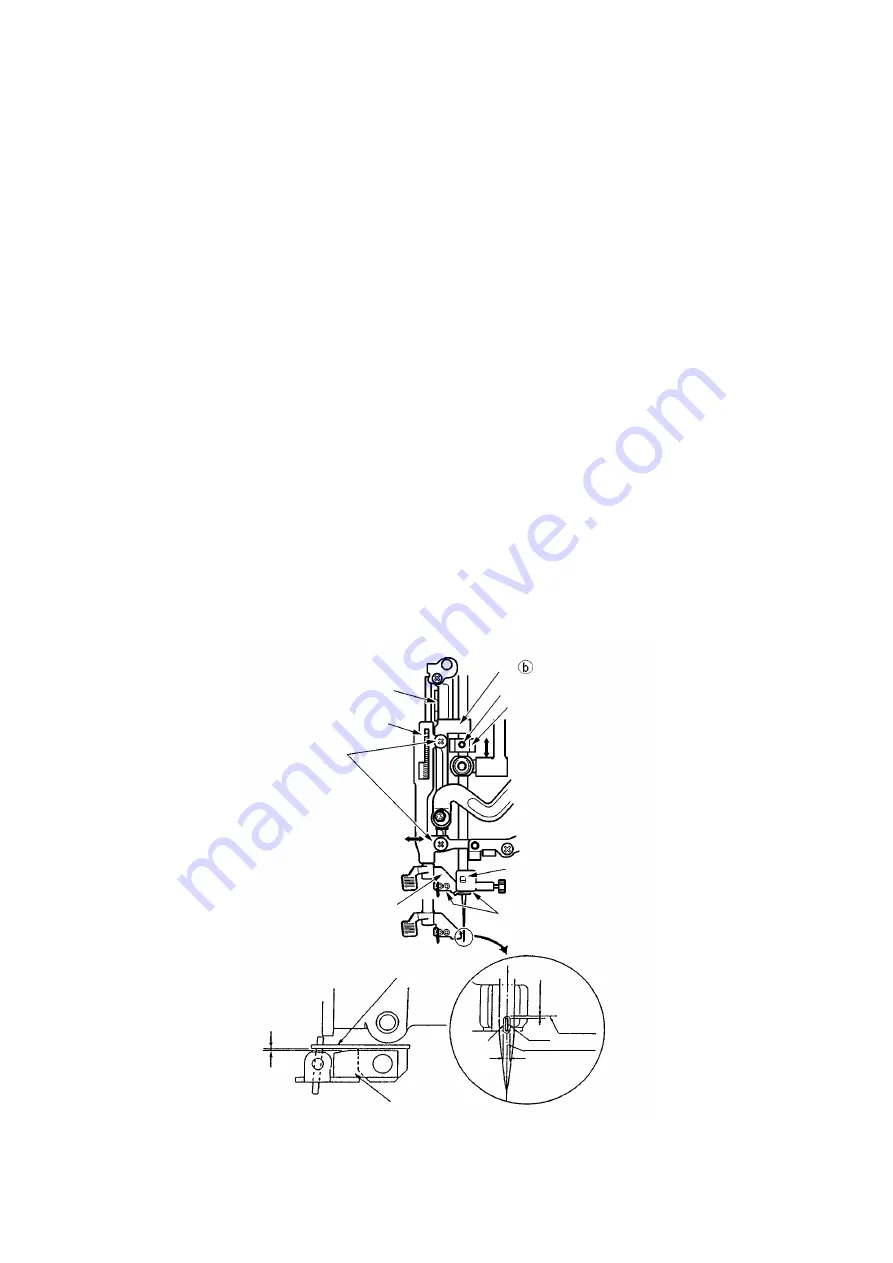

NEEDLE THREADER

(CHECKING THE HOOK POSITION IN THE HORIZONTAL DIRECTION)

STANDARD

Needle threading should be possible when the needle holder bottom surface and hook holder bottom surface

height have been aligned.

* Left-right direction relative to the needle hole

The hook left-right direction reference position should be at the needle hole center. (The clearance between the

hook and the left and right of the needle hole should be the same.)

* Up-down direction relative to the needle hole

The clearance between the hook and top end of the needle hole should be 0-0.1 mm.

ADJUSTMENT

1.

Turn the balance wheel and adjust to the needle holder bottom surface and hook holder bottom surface

height. (Use eight #11 or #14 needle.)

2.

Loosen the two screws securing the needle threader base.

3.

Move the needle threader base left and right and adjust so that the hook comes to the center of the needle

hole, then tighten the two screws securing the needle threader base.

4.

Loosen the screw securing the positioning support.

5.

Adjust the positioning support up and down so that the clearance between the hook and the top end of the

needle hole is 0-0.1 mm.

6.

Check that the threader positioning and needle bar base are parallel, then tighten the screw securing the

positioning support.

*

If the threader positioning and needle bar base are not parallel, the threader positioning can contact of the

needle bar base and break the threader.

Screw securing positioning

Positioning support

Needle

hole

Needle bar base

Parallel

Threader positioning

Align

Needle holder

Needle bar base

Hook holder

Screw securing threader base

Threader base

Threader positioning

Top end of

needle hole

0-0.1 mm

Center of needle hole

Hook