10

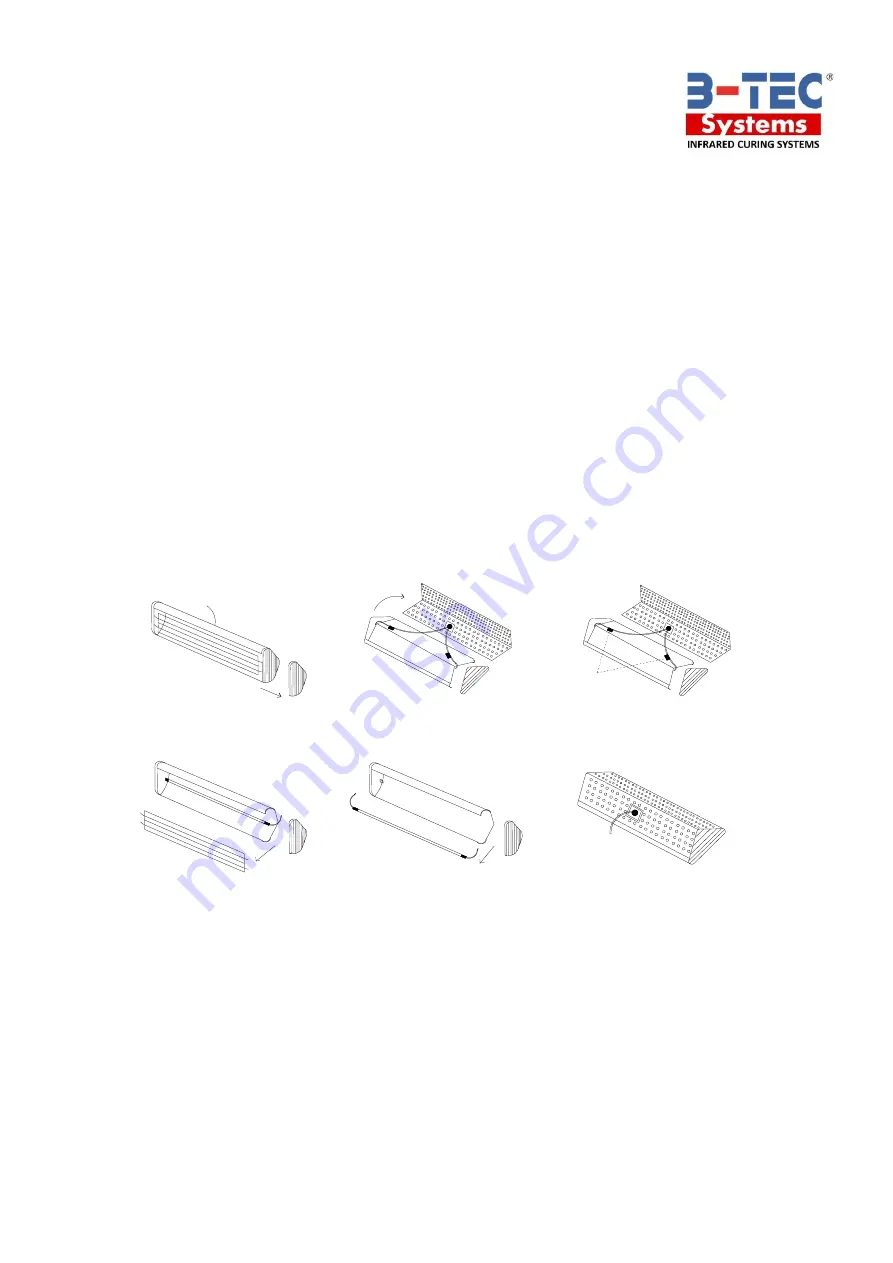

6. Replacement of Emitter Lamp Tube

Un-plug from the power supply, before replacing the infrared emitter / tube.

1. Remove the side panel.

2. Release the radiating panel.

3. Loosen the two leads in the lamp and remove them.

4. Remove the protective grill in front of the emitter.

5. Take out the defective emitter and fit the new emitter after checking that the part you

purchased is correct. Ensure that you attach the wires correctly.

6. Install the protective grill, radiating panel and the side panel.

Use a piece of soft cloth or cotton to clean the reflector panel and the emitter with alcohol.

Cleaning must be conducted after the machine is disconnected from the power source and

cooled down if necessary. Do not restart the equipment until all solvent / cleaning fluid

residue has evaporated. 15 minutes advised as the evaporation time.

Disconnect

the wires of the emitter

1

2

3

4

5

6

Summary of Contents for IR-B01

Page 1: ...Infrared Model IR B01...