Installation guide, 'Pickle Fork' Back-and-Forth Model Train Controller

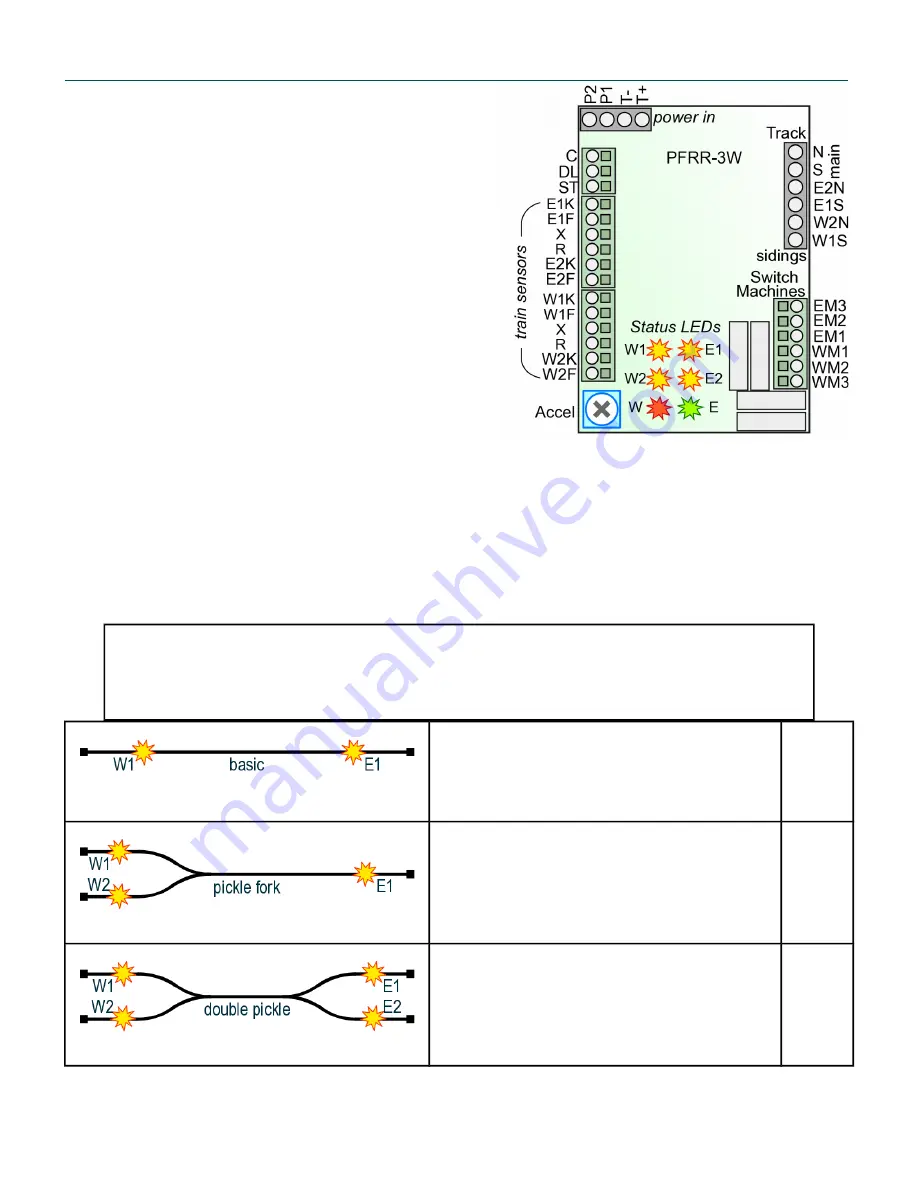

Azatrax model PFRR-3W

This controller can automate a 'back-and-forth' model train layout

with optional siding at either or both ends of the layout -- or, one

train can travel continuously around a loop, making stops at

predetermined locations.

Requirements:

Trains must be DC powered

, not DCC or AC, because train

direction is controlled by the polarity of the track power.

Maximum track current: 2 amps (2.5 amps for acceleration).

If turnouts (track switches) are used, the turnouts must be operated

by

switch machines with 3-wire control cables

. These are 'snap'

type switch machines with twin coils such as Atlas, Bachmann or

Peco.

If your turnouts have switch machines with 2-wire control cables,

use the Azatrax PFRR-2W control circuit.

An accessory power supply, 12 to 17 volts AC or DC is required to run the PFRR circuit. This is separate from the track

power.

This power supply must have sufficient current capacity to operate the switch machines -- typically 2 amps or more.

Train sensors:

One train sensor must be installed at each track location where a train is to stop. One sensor is needed at each track end

point. Additional sensors or external detectors may be added for station stops where a train will momentarily stop, then

continue in the same direction.

The PFRR controller has connections for up to four train sensors. They are numbered W1, W2, E1 and E2.

The operating mode of the PFRR is determined by the combination of sensors that are connected.

So be careful to connect your sensors to the correct terminals on the PFRR controller. The wrong

combination will result in unexpected operation.

Back and forth, no turnouts

Connect sensors:

Do not connect W2

W1 at west end

E1 at east end

E2 may be used as a station stop between W1 & E1.

External detectors may also be used for station stops.

see

page

2

Back and forth, one turnout

Connect sensors:

Do not connect E2

W1 at west end, track 1

W2 at west end, track 2

E1 at east end

Use external detectors for station stops if desired.

see

page

2

Back and forth, two turnouts

Connect sensors:

W1 at west end, track 1

W2 at west end, track 2

E1 at east end, track 1

E2 at east end, track 2

Use external detectors for station stops if desired.

see

page

2

azatrax.com © 2017

Azatrax Pickle Fork RR Installation, 3-wire switch machines

rev. C1 pg. 1 of 7