SM-900.4407

A-2-H Actuator Positioners

Service Information

The user of these devices must conform to all applicable

electrical, mechanical, piping and other codes in the

installation, operation or repair of these devices.

INSTALLATION!

Do not attempt to install, operate or repair

these devices without proper training in the technique of

working on pneumatic or hydraulic systems and devices,

unless under trained supervision.

Compressed air and hydraulic systems contain high levels of

stored energy. Do not attempt to connect, disconnect or

repair these products when a system is under pressure.

Always exhaust or drain the pressure from a system before

performing any service work. Failure to do so can result in

serious personal injury.

MOUNTING!

Devices should be mounted and positioned in

such a manner that they cannot be accidentally operated.

WARNING: INSTALLATION AND

MOUNTING

The A-2-H Actuator Positioner is a pneumatic positioner

used where accuracy is required and when the device to be

operated has low-force characteristics. Typical applications

are positioning the butterfly valve of carburetors and the

control arm of diesel engine governors.

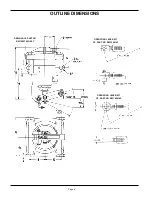

INSTALLATION and ADJUSTMENT

Mount the positioner firmly to the engine frame to

prevent relative motion between the operating lever

and the engine control arm. The positioner should be

installed with its operating lever in the same plane as

the engine control arm. Avoid interference with the

connecting link which could cause friction and

inaccuracy. Adjustable clevis and ball joint lever

attachments are available.

Full travel range of the positioner should be utilized

and the end travel of the lever attachment and the

engine control arm must match. The lever with

attachment is adjustable in length from 3 ¾ inches to

4 ½ inches (95mm to 114mm), which alters the end

travel from 1 7/8 inches to 2 ¼ inches (48mm to

57mm). For decreased lever travel, loosen jam nut

(100) and screw the attachment farther into the

operating lever. Tighten the jam nut to secure this

position. Lever travel can be increased by

unscrewing the attachment and then tightening the

jam nut.

If the end travel of the engine control arm exceeds

the maximum adjustment of the operating lever, the

normal procedure is to drill a hole in the control arm

at a point which has a travel range of two inches.

Fasten the connecting link to the new hole and

readjust the end travel of the control arm and

operating lever to match.

As assembled, the adjustable elements of the

positioner are matched to provide zero lever travel

with indicated preload pressure (usually 10 psi or 0.7

bar), and maximum lever travel with rated top

pressure (usually 60 psi or 4.1 bar).

The push rod travel is factory-set to correspond to

rated top pressure. If the top pressure of the control

valve is greater or less than that of the positioner, the

travel of the control valve handle can be made to

match the travel of the operating lever by using the

push rod travel adjusting screw (15).

Two or more positioners can be matched to

provide the same movement for a given change in air

pressure. They can also be deliberately mismatched

to provide different lever travel to compensate for

inequalities in operating characteristics of the

controlled device. If necessary to adjust for incorrect

initial pressure, remove or add shims (9 and 10) as