Avant e6

85

.

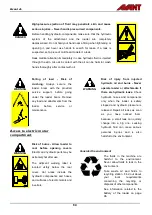

Installing of service support and frame

lock

Installing boom service support:

The red service support of the boom lift cylinder is

located at the tip of the boom, behind the attachment

coupling plate.

Make sure that the boom stays up during

maintenance operations by putting the service

support on the lift cylinder piston rod. Secure the

service support by locking it on the piston rod with

the long screw that is on the support.

Service support stored at the tip of the boom

Service support in place

Frame lock:

A red frame lock bar is stored under the operator's

cab.

This lock bar is intended to lock the articulated frame

to make the loader frame stay straight during e.g.

lifting or transportation.

The holes for the frame lock bar are on the left side

of the loader, below the access step.

1.

Slide the hook type end of the bar through a

hole on the rear frame of the loader.

2.

Turn the bar towards the front hole. The other

end should remain locked in the hole on the

rear frame.

3.

Align the holed end of the bar and the frames

by turning the steering wheel. This can be

done without starting the loader.

4.

Once aligned, slide the bar and lock with its

cotter pin.