7

Rev. (30-JAN-98) • RLM v4.7

© 1995-98 Automated Logic Corporation

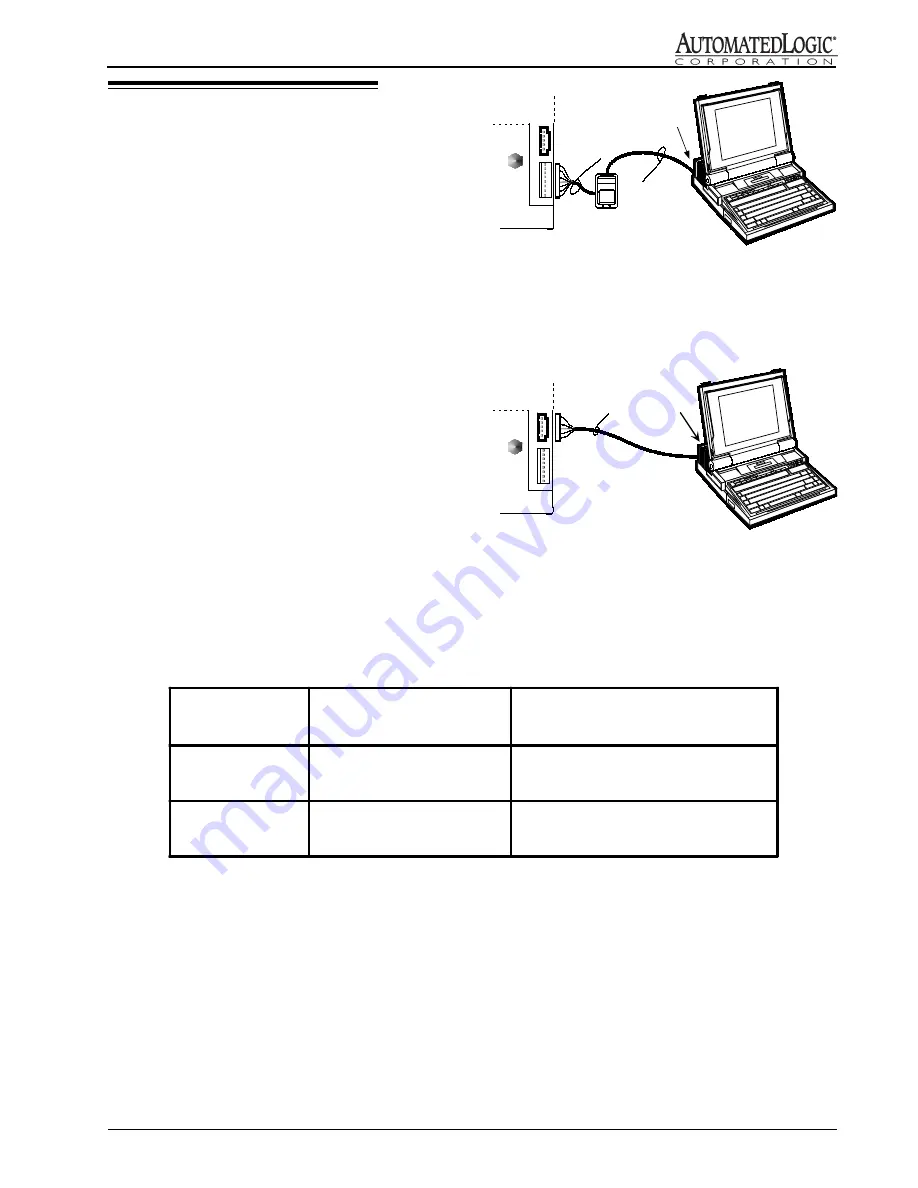

Figure 9: Connecting to the ZONE port

Local Access

The R683 allows you to connect a computer to the

ACCESS port or the ZONE port. You can connect to the

ZONE port either at the module or through an Enhanced

Zone Sensor (see Figure 9). The computer’s connection

type must be set to Direct Network.

The ZONE port uses an 8-pin connector. To make a cable

for this connection (see Figure 7), use ALC part no. CON,

a package of 8-wire connectors and covers (AMP part

no’s. 641237-8 and 640550-8) which require 22 AWG

stranded wire. Other connectors are available by calling

your local Amp distributor at 800-526-5142. The cable

wiring configuration is shown below. The cable should

not exceed 50 ft. See Figure 11 for how to use the

switches on the NI485 cable.

NOTE: When making a sensor cable, disregard the

numbers imprinted on the plastic connector.

The ACCESS port uses a 5-pin connector. To connect to

this port, use the NI485 cable head and the 235015 cable

(see Figure 10). See Figure 11 for how to use the switches

on the NI485 cable.

N I4 8 5

C a b l e

H e a d

2 3 5 0 1 5

C a b l e

R 6 8 3

ACCESS

ZONE

R S Z +

N I4 8 5

C a b l e

H e a d

R 6 8 3

ACCESS

ZONE

A L C

p a r t n o .

C O N

2 3 5 0 1 5

C a b l e

Figure 10: Connecting to the ACCESS port

Figure 11: NI485 Switch Table

NI485 Switch

Position

Module ACCESS Port

5 position

ZONE Sensor Port

8 position

Network

connected to module

connected to net

disconnected from the module

disconnected from the net

Isolated

connected to module

disconnected from net

connected to module

disconnected from net