12

Assembly Instruction

OFV1

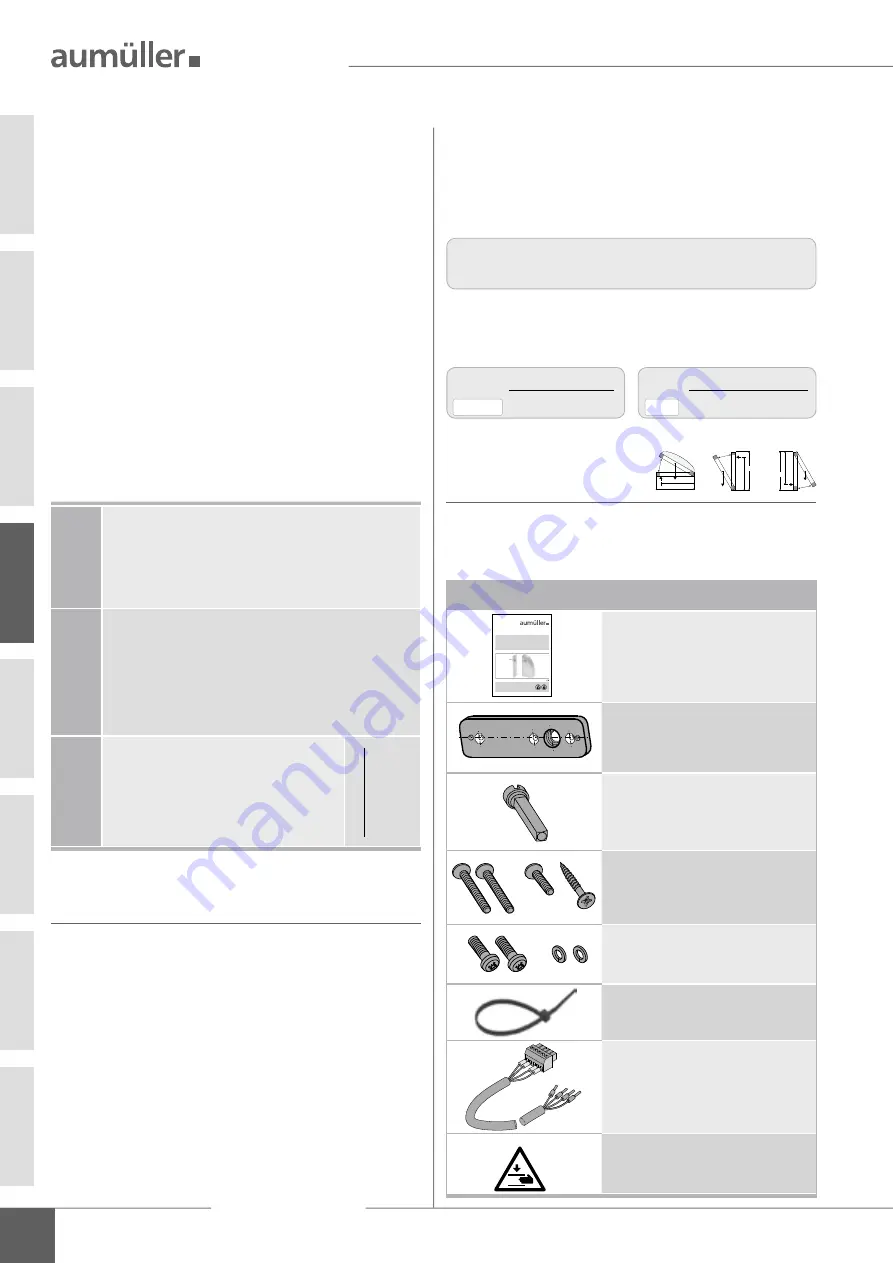

Accessories for locking drive

Assembly and Commissioning

Instructions

1x Adapter plate

1x Square: Vk 7 x 55

2x Countersunk screw M 5 x 40

1x Countersunk screw M 5 x 16

1x Spax countersunk screw 4,5 x 30

2x Head screw M 5 x 16

2x Spring rings

1x Cable fastener

1x Connecting cable with plug

1x Warning sign sticker

„Risk of entrapment“

nach Maschinenrichtlinie 2006 / 42 / EG (Anhang VI)

OFV1 - OLIVEN-FLÜGEL-VERRIEGELUNGSANTRIEBE FÜR FENSTER

Anweisung für

Montage und Inbetriebnahme

1 2 3

4 5

Tools required

• Marker,

• Grains,

• Hammer,

• Knife,

• Screwdriver (cross, Torx),

• Hexagonal wrench,

• Torque wrench,

• Power drill,

• Threadlock adhesive,

• possibly a tool for blind rivet nuts.

Scope of delivery:

Prior to assembly, check items quantity in the delivery for

completeness.

Check window data on site

• Measure FAB and FAH.

• Check / calculate weight of casement.

If unknown, it can be determined approximately with

the following formula:

• Check / calculate the required drive force and compare

with drive data . If unknown, it can be determined

approximately with the following formula:

a

= Distance of action point to hinges

F

= Drive force

s

= Stroke

weight) [kg]

[m]

[m]

[mm]

frame

share

glass-

density

G

(Casement =

FAB

*

FAH

*

Glass thickness

*

2,5

*

1,1

F

[N] =

Facade

Roof

F

[N] =

5,4

*

G

[kg]

*

s

[m]

5,4

*

G

[kg]

*

FAH

[m]

a

[m]

a

[m]

I

nstallatIon

step

2:

i

nstaLLatiOn

prerequisite

and

i

nstaLLatiOn

preparatiOn

The following conditions must be fulfilled for the instal-

lation of the drives so they can be properly assembled with

other parts and constructed to a complete machine at the

window without impairing the safety and health of persons:

1. The design of the drive must fulfill the requirements.

2. The fastening accessories (casement brackets or

frame brackets) must fit the window profile; the

profile-dependent hole lay-out must be complied with.

3. The space required for the installation of the drive on

the frame and casement profile must be sufficient.

4. The window must be in perfect mechanical condition

before the installation. It should open and close easily.

5. The fastening material for the installation of the drive

must fit the window material (see table).

P

reParing

assembly

04

W

ood windows

Wood screws:

i.e. DIN 96, DIN 7996, DIN 571

round head with slot,

round head with cross,

hex head,special type

steel,

stainless steel,

aluminum windows

Self-tapping screws, thread screws,

sheet-metal screws

i.e. ISO 4762, ISO 4017, ISO 7049 , ISO 7085, DIN 7500

cylinder head with hex socket, internal serration (Torx),

Phillips head or external hex head

blind rivet nut

plastic windows

Screws for plastic

i.e. DIN 95606, DIN 95607, ISO 7049,

ISO 7085, DIN 7500

round head with cross, external hex head,

Torx

Recommendation

:

if possible

, screw

through two cavity

webs

a

a

a

G

G

s

s

s

FAH

G

F

F

F

FAH

FAH