7

January 2004

GPT ARGUS

Cleaning the ARGUS Validator

Depending on its environment and amout of use, the

Argus Bill Validator may require periodic cleaning to

restore the unit to optimum performance. Under nor-

mal use, it should be cleaned every 6 month. For

unusual operating conditions more frequent cleaning

will be required.

1. Open Main Door and turn power off.

2. Slide the Bill Validator Tray out.

3. Disconnect the connector cable and remove the

Bill Validator Head from its mounting frame.

4. Open the Bill Validator Head by releasing the

spring-loaded latches and swinging out the Up-

per-Guide Assembly.

5. Use a soft cotton cloth dampened with 90% iso-

propyl alcohol to carefully clean all parts in the

Bill Channel. Remove all deposits from the rollers.

Note

: Do not scrach any area, as this can dam-

age the Validator.

- Do not allow liquid to enter the Vallidator Unit, as

this can damage electrical components.

- Do not use unapproved cleaners, as this can dam-

age the surface of the optics.

- Do not use cotton swabs, as this can leave un-

wanted material in the Bill Channel.

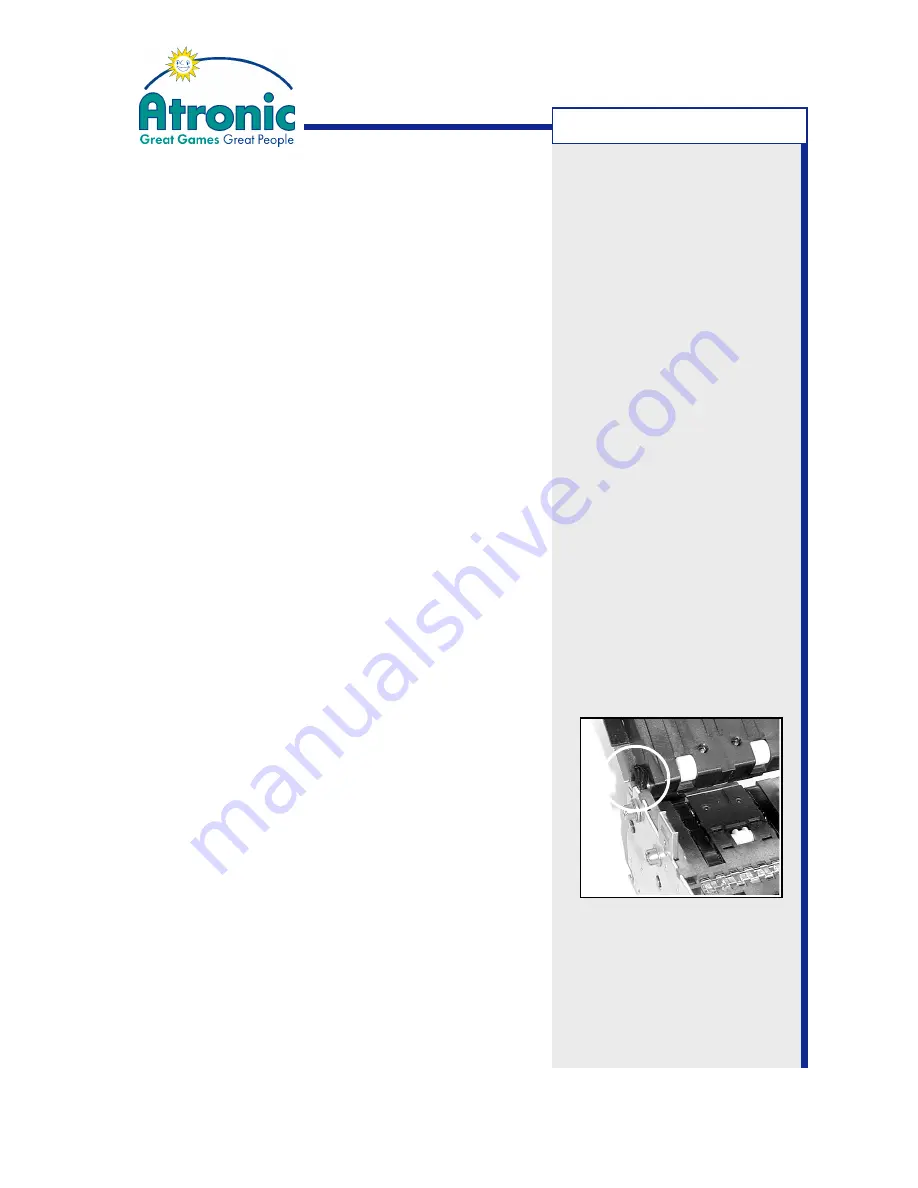

6. Carefully swing the Upper-Guide Assembly back

to its fully closed (locked) position. Make sure no

cable is squeezed by the Upper Guide Assembly.

7. Mount the Bill Acceptor Head back into its mount-

ing frame and connect the connector cable

8. Slide the Bill Validator Tray in. Make sure that it

is clamped in its position.

9. Apply power and close the Main Door. The Argus

Bill Acceptor is now operational.

The use of Validator Cleaning Cards is not recom-

mended. These cards need to rub against the optic

and magnetic head in order to clean the components.

In the ARGUS validator the optics are recessed and

therefore cannot be reached by the Cleaning Card.

Note

: Do not squeeze

cables when closing the

Validator Head.

V

ALIDATOR

H

ANDLING