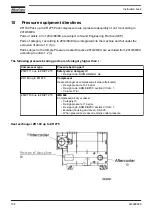

Activities

Level A

Level B

Level C

Check critical bolt/coupling connections

X

X

X

Check operation of safety valves

X

X

X

Check for presence of water in lube oil

X

X

X

Change Roto Z oil (16000 hrs or 2-yearly)

-

-

X

Inspect/change air filter element(s)

X

X

X

Check condition of air intake chamber

X

X

X

Change compressor oil filter (4000 hrs or annually)

X

X

X

Replace filter element of gear case breather

X

X

X

Check cycle of air intake throttle valve

X

X

X

Replace diaphragm of air throttle valve

X

X

Overhaul air intake valve

X

Check functioning of check valve (8000 hrs or annually)

X

X

X

Overhaul check valve

X

Check condition of balance piston diaphragm

X

X

-

Change balance piston diaphragm

-

X

X

Check/Service condensate drain(s)

X

X

X

Overhaul drain(s)

-

X

X

Grease main drive motor bearings (according to motor data

plate)

X

X

X

Clean fan cowl of electric motor

X

X

X

Check rubber inserts of drive coupling (arr. E)

X

X

Replace inserts of drive coupling (arr. E)

X

Check condition of drive gear teeth

X

X

Take and record all S.P.M. readings. On VSD compressors

also register the motor speed

X

X

X

Inspect electrical contactors

X

X

X

Check all electrical connections

X

X

On VSD compressors, if applicable, replace motor carbon

brush

X

On VSD compressors, if necessary, clean electrical cabinet

with vacuum cleaner

X

X

X

Check oil quantity

X

X

X

Replace shaft seal

-

-

X

6.2

Motor greasing

General

Stop the compressor and follow the LOTO procedure (Lock Out - Tag Out) (refer to

General Safety Precautions) before greasing.

Never mix greases of different brands or types.

Instruction book

AIF999999

91

Summary of Contents for ZR 200

Page 1: ...Instruction book AIF999999 ZR 200 ...

Page 2: ......

Page 61: ... CORRECT installation Instruction book AIF999999 59 ...

Page 108: ......

Page 109: ......