- 93 -

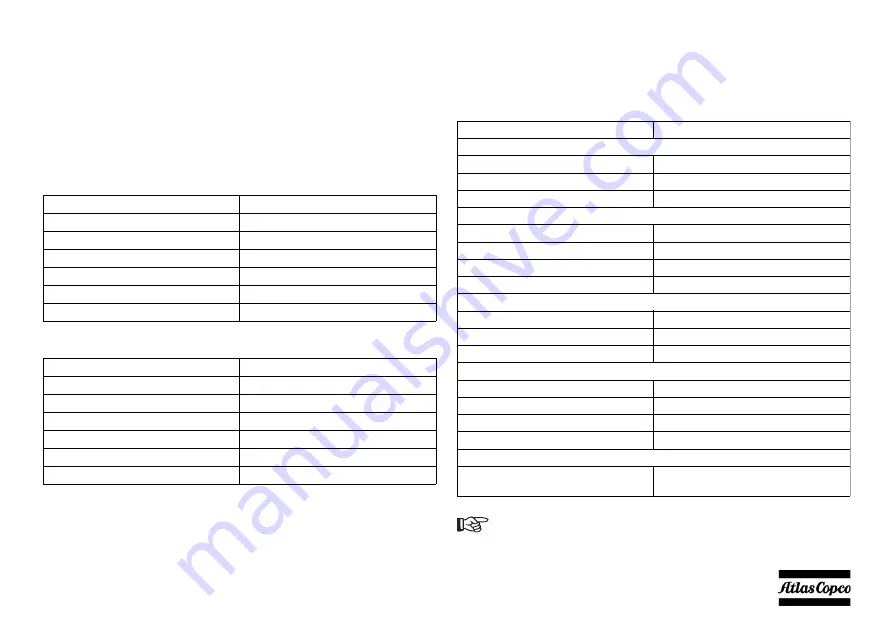

Technical specifications

TORQUE VALUES

GENERAL TORQUE VALUES

The following tables list the recommended torques applied for general applications

at assembly of the compressor.

For hexagon screws and nuts with strength grade 8.8

For hexagon screws and nuts with strength grade 12.9

CRITICAL TORQUE VALUES

Thread size

Torque value (Nm / lbf.ft)

M6

9 (7)

M8

23 (17)

M10

46 (35)

M12

80 (60)

M14

125 (93)

M16

205 (152)

Thread size

Torque value (Nm / lbf.ft)

M6

15 (12)

M8

39 (29)

M10

78 (58)

M12

135 (100)

M14

210 (155)

M16

345 (255)

Assemblies

Torque value (Nm / lbf.ft)

Axles to frame:

Wheel nuts

270 (200)

Bolts, front axle/frame

205 (152)

Bolts, rear axle/frame

205 (152)

Compressor to frame:

Bolts, elements/gear casing

46 (34)

Bolts, elements/support

80 (60)

Bolts, support/buffer

205 (152)

Bolts, buffer/frame

80 (60)

Engine to frame:

Bolts, engine/support

205 (152)

Bolts, support/buffer

46 (34)

Bolts, buffer/frame

23 (17)

Lifting beams to frame:

Bolts, lifting beams/yoke (M12)

125 (93)

Bolts, lifting beams/yoke (M16)

205 (152)

Bolts, lifting beams/A-Frames

205 (152)

Bolts, A-Frames/frame

205 (152)

Hose clamps:

Pebra hose clamps on all IC/radiator

hoses

12 (9)

Secure the drain cock and tank cap of the fuel tank handtight.

Summary of Contents for XRHS 1150 CD4 C3 WUX

Page 2: ......

Page 16: ... 16 Main parts ...

Page 18: ... 18 REGULATING SYSTEM ...

Page 21: ... 21 ELECTRIC SYSTEM 9822 0963 40 C13 HP ...

Page 105: ......

Page 106: ...www atlascopco com ...