60

3.4

Platform operation safety devices

Warning: Periodically verify that the safety devices are operating correctly.

During work, the operator must be able to assess, recognize and avoid all

dangers and must immediately inform the persons in charge of any faults in the

safety devices so that they can be inspected and restored to their original

conditions of safety and reliability

DO NOT TAMPER WITH AND DO NOT CHANGE THE CALIBRATION OF ANY OF

THE COMPONENTS OF THE ELECTRICAL AND HYDRAULIC SYSTEM.

The platform comprises a complete set of safety devices.

3.4.1

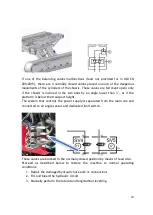

Main frame inclination control device

On the machine Frame there is a Can Bus angle sensor that constantly

communicates the inclination measured to the electronic control unit.

The angle sensor is redundant (thus consisting of two separate sensors) and the

X and Y inclination axes of the machine are monitored (lateral and longitudinal)

The signals of the two sensors are constantly compared with each other to assess

their consistency.

The device is placed under a cover positioned inside the scissors.

Summary of Contents for 1090 EVO

Page 7: ...7...

Page 22: ...22...

Page 23: ...23...

Page 49: ...49 37 Combustion engine 38 Fuel tank 39 Bi levelling chassis 37 38...

Page 78: ...78...

Page 80: ...80...

Page 122: ...122 In this configuration the oil level must be as shown in the figure below A 60mm...

Page 144: ...144...

Page 145: ...145...

Page 146: ...146...

Page 147: ...147...

Page 148: ...148...

Page 149: ...149...

Page 150: ...150...

Page 151: ...151...

Page 152: ...152...

Page 161: ...161 8 ATTACHMENTS 8 1 Declaration of conformity...

Page 163: ...163 MANDATORY ROUTINE INSPECTIONS Date Observations Seal Signature...

Page 177: ...177 8 4 Hydraulic diagram See attachment 8 5 Wiring diagram See attachment...