® Copyright by ATH-Heinl GmbH & Co. KG, 2014, All rights reserved /Misprint and technical changes reserved / Issue: 12/2014

- 27 -

Maintenance and service instructions

All maintenance and service works should be done at least once a month

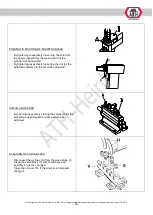

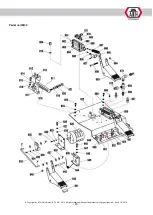

COMPRESSED AIR MAINTENANCE UNIT

ADJUSTMENT OF WORKING PRESSURE:

-

Check the working pressure which is indicated in the

manometer (1). The pressure has to fulfill the

technical data.

-

The working pressure can be adjusted by means of

the pressure controller (A).

-

Pull the pressure controller upwards in order to make

adjustments.

-

For increasing the pressure in the machine you have

to turn the pressure controller clockwise, for

decreasing the pressure you have to turn it counter-

clockwise.

OILER

-

Check the oil level in the oil tank (3)

-

Remove the oil tank

-

Refill now the tank accordingly with a pneumatic oil,

viscosity SAE20.

-

Check the rate of injection of the oil in the viewing

glass (4). The oiler is working correctly if one drop of

oil injects automatically into the compressed air

system while pressing the bead breaker twice.

-

If this is not the case, the oil quantity to be injected

has to be adjusted with the regulating screw (C).

Normally the screw has to be tightened completely

clockwise and then opened appr. ¼ to ½ rotation

counter-clockwise.

WATER SEPARATOR

-

Check the water level in the separator (2).

-

By opening the valve (B) the water will be drained.

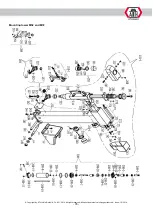

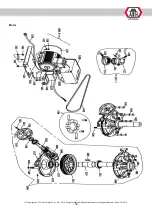

TENSION OF V-BELT

-

The worm gear (3) is driven by the V-belt (2) of the

motor (1).

-

For tensioning you have to loosen the fixing screws of

the motor.

-

Following the counter nut (B) must be loosened.

-

By turning the screw (A) the V-belt will be tensioned.

Thereby the V-belt should ease by pressing (in the

middle) maximum 8 mm.

-

For the final fixation the counter nut (B) and all fixing

screws of the motor has to be tightened again.

-

Finally only the covers hast o be mounted again.

A

B

C

1

2

4

3

3

2

1